04-30-2016, 03:22 PM

Thought I'd bore all of you with a progress report ...

Pete has been extremely patient while I waited for the additional tool holders to show up. They arrived the other day so this morning it was time to solve the "how to ship heavy stuff to Australia" problem.

First thing was to get some tools and materials ...

Next step was to add some foam around the inside of the box ...

Next was to see if the pieces would fit inside the lined box ...

Well that seems to have worked out. But there is a significant problem that needs to be solved. These are heavy pieces of metal and during transit they will move around and probably damage one another and the box, possibly escaping thru the holes they would make. If only there was a way to inject foam into all of the blank spaces. But if I did that then Pete would have a heck of a time getting all the foam off the tools.

After a little thought I proceeded up stairs and asked Bev if I could borrow the vacuum food sealer for a little while. I was surprised that it actually seemed to work ...

And now to see if it still fits ...

Ok, I admit that the vacuum sealer seemed to work but (a) after the first couple of items it was boring and (b) after a few minutes it seemed like air was leaking into the bag. Given that it was not the extremely tight form fitting packaging I was hoping for I put everything for the next box in individual zip lock bags and squeezed as much air out of them as I could. A rubber band around the top and it looked like it was good to go.

Now the fun part. Some disposable gloves and then some Great Stuff Gaps and Cracks ...

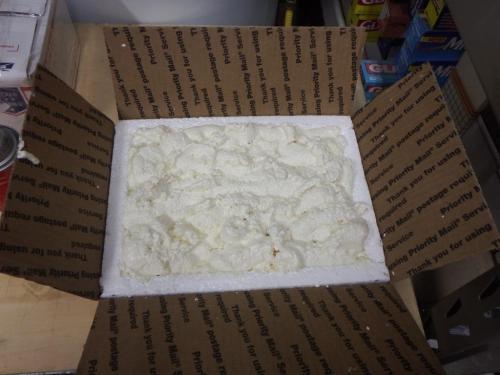

When the box was full of foam I put the final piece of white foam board across the top as a lid and then taped the box up.

I'd weighed them before I started foaming and each was about 18lbs which is perfect for the 20lbs limit at the post office. On Monday morning we'll go to the Prior Lake post office and send them on their way.

When Pete gets the boxed he will have to dig and cut all of the pieces out of the foam, but hopefully they all be intact.

Pete has been extremely patient while I waited for the additional tool holders to show up. They arrived the other day so this morning it was time to solve the "how to ship heavy stuff to Australia" problem.

First thing was to get some tools and materials ...

Next step was to add some foam around the inside of the box ...

Next was to see if the pieces would fit inside the lined box ...

Well that seems to have worked out. But there is a significant problem that needs to be solved. These are heavy pieces of metal and during transit they will move around and probably damage one another and the box, possibly escaping thru the holes they would make. If only there was a way to inject foam into all of the blank spaces. But if I did that then Pete would have a heck of a time getting all the foam off the tools.

After a little thought I proceeded up stairs and asked Bev if I could borrow the vacuum food sealer for a little while. I was surprised that it actually seemed to work ...

And now to see if it still fits ...

Ok, I admit that the vacuum sealer seemed to work but (a) after the first couple of items it was boring and (b) after a few minutes it seemed like air was leaking into the bag. Given that it was not the extremely tight form fitting packaging I was hoping for I put everything for the next box in individual zip lock bags and squeezed as much air out of them as I could. A rubber band around the top and it looked like it was good to go.

Now the fun part. Some disposable gloves and then some Great Stuff Gaps and Cracks ...

When the box was full of foam I put the final piece of white foam board across the top as a lid and then taped the box up.

I'd weighed them before I started foaming and each was about 18lbs which is perfect for the 20lbs limit at the post office. On Monday morning we'll go to the Prior Lake post office and send them on their way.

When Pete gets the boxed he will have to dig and cut all of the pieces out of the foam, but hopefully they all be intact.

That's a heap of effort you've gone to to get these packed for the journey Arvid, now I'm starting to get excited.

That's a heap of effort you've gone to to get these packed for the journey Arvid, now I'm starting to get excited.