Posts: 59

Threads: 14

Joined: Jan 2015

Location: UK

Maybe I should shoot a video if thats easier so you can see the whole lot in context.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

The following 1 user Likes Pete O's post:

Dan Boy (10-07-2023)

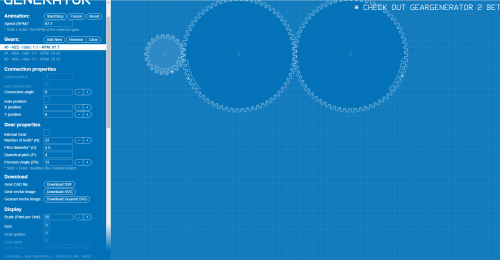

I'm far from an expert Dan, but I guess you have a number of options for speed reduction across that gear train; smaller gear on the lathe spindle (chuck shaft) (the fwd/rev tumble pair would need to still be able swing into mesh); larger gear on the big side of the compound gear; smaller gear on the small side of the compound gear; larger gear at the final driven shaft. I think I'd start by seeing if it is possible to achieve the desired reduction by rearranging the gears you already have; if not (probably not) then I'd look at the most economical place in the chain to achieve it, i.e. where the least number of new gears are needed. It looks like it might be possible to put a bigger 'big' gear on the compound set without needing to change any of the idlers, as the banjo can adjust (swing) to accommodate that? Looks like the way the banjo is made, a bigger gear at the final driven end will necessitate a new idler and unfortunately the banjo has been manufactured without a way to accommodate this.

One of the electronics wizzes on here could probably devise a way to drive the leadscrew electronically at an infinitely variable relationship to the spindle. That would be cool. Possibly end up cheaper than gears!

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 759

Threads: 46

Joined: Mar 2012

Location: Rochester, NY

The following 2 users Like rleete's post:

Highpower (10-07-2023), Dan Boy (10-07-2023)

Varmint Al did something like that many years ago. I always intended to try it, but never got around to it.

http://www.varmintal.net/alath.htm#Ultra_Fine

Full of ideas, but slow to produce parts

Posts: 59

Threads: 14

Joined: Jan 2015

Location: UK

Well, that is a very interesting point regarding motorising the lead screw. If I did that I could just keep the banjo gear chain to one side.

I wonder how much HP on a motor I would need for the lead screw. I think not much.

Posts: 59

Threads: 14

Joined: Jan 2015

Location: UK

Just been out to the workshop. To turn the lead screw takes very little effort even though it is going through the gear box.

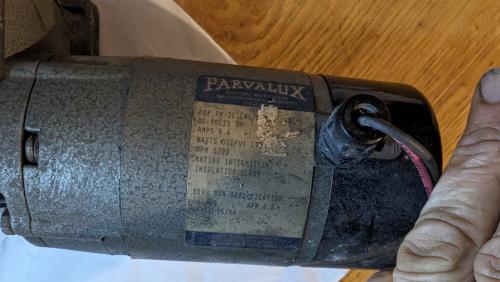

Now I have this 24v motor that I am intending to use for a powered bead roller I'm building but maybe I should use it on the lathe.

The plate on the motor is not easy to read but looks to be an output speed of 6.8 RPM. I guess I don't know the duty rating of this motor or how much load will be on it turning the lead screw while I am cutting material. But maybe I should mock it up and see how it performs.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Looks like you have yourself project. A much smarter person than me would be able to synch the motor to an encoder on the spindle for thread cutting. I'm off on holiday so I'll be interested to see what you've done when I get back.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.