Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

The following 3 users Like Brian's post:

f350ca (02-16-2016), EdK (02-16-2016), Mayhem (02-16-2016)

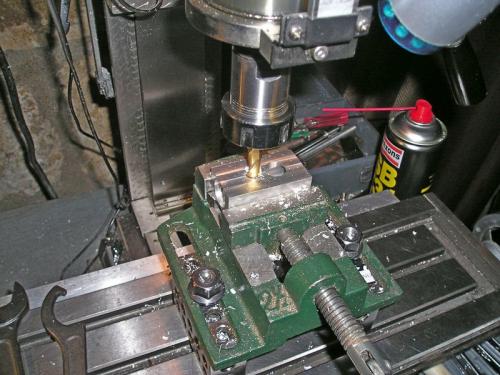

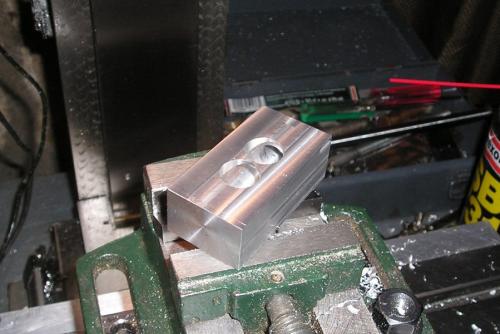

Latest pick's of making the cam box the hole at the side is so the valve clearances can be set, if I drill many

more holes in this thing I will have nothing left.

Brian

Posts: 432

Threads: 27

Joined: Feb 2016

Location: Woodstock:GA

Brian,

The vice jaw width, is it 4 inch? Trying to get grasp of the size of the cam box. That head is much bigger than it looks ... cool looking head. The head design is where most of the power is produced. Got to say you move right along with the machining ..... Fascinating that you made the valve seat cutters and install tools btw. Hopping over to the link I just spotted .

Greg

Magazines have issues, everything else has problems

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

Hi Greg.

The vice is 2-1/2", cam box length 58mm Head diameter 56mm, Valve diameter 9mm The overhang at the back covers part of the cam drive pulley and the front edges will be chamfered to conform closer to the curve of the head, Inside the cover of the side access will be a felt pad to supply oil to the cam and follower's.

I hope you enjoy my web site it's a little messy right now I cant seem to find the time for everything these days

All the lathe and mill mods are free just down load the PDF's All of them are on this forum somewhere as well.

Brian

Posts: 432

Threads: 27

Joined: Feb 2016

Location: Woodstock:GA

Thanks Brian,

I did read the pdf's, found the information interesting, you get a lot out of the machines you have. The upgrades are smart and imaginative.

Magazines have issues, everything else has problems

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

The following 3 users Like Brian's post:

f350ca (02-17-2016), EdK (02-17-2016), Pete O (02-17-2016)

The next stage is to drill the holes to attach the cam box , to do this the box must be perfectly in line with the head, so a pair of stepped dowels where made to match the cam follower bore to the holes in the bottom of the box.

Now I can drill them as a pair tapping size then open out the box holes to just clear the screws

Brian.

Posts: 8,742

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Mayhem (02-17-2016)

stuff Brian.

Ed

Posts: 432

Threads: 27

Joined: Feb 2016

Location: Woodstock:GA

Good thinking... Bottom shot, funny how the lighting makes the cam box appear as if it has the same pattern as the grain in the desktop..

Magazines have issues, everything else has problems

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Nicely done Brian

DaveH

a child of the 60's and 50's and a bit of the 40's

Posts: 2,596

Threads: 99

Joined: Dec 2014

Location: Michigan

stuff Brian.

stuff Brian.