12-07-2013, 09:35 AM

As you may have already read in this post, I redesigned the drive set up, as the previous owner had used a rather scary system to replicate the overhead line shaft that was the norm when this lathe was made.

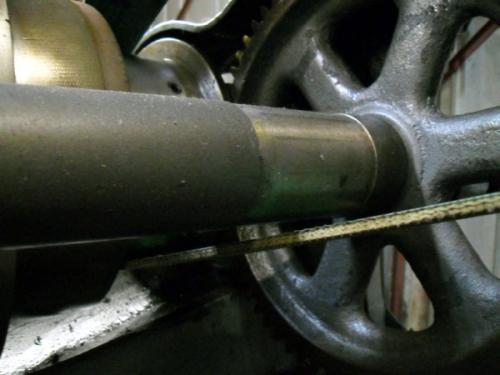

Whilst I am very happy with the solution I came up with, I soon discovered that the flat belt rubbed on the back gear when in high range. I finally got around to making a roller to change the belt path, so that it doesn't rub. The bearing holders were made out of some scrap and the roller was turned from a roller from a photocopier.

I had to modify the pivot point on the drive frame, as the head of the bolt I was using fouled the bearing holder. I will remove it and paint it now that I have tested everything.

Whilst I am very happy with the solution I came up with, I soon discovered that the flat belt rubbed on the back gear when in high range. I finally got around to making a roller to change the belt path, so that it doesn't rub. The bearing holders were made out of some scrap and the roller was turned from a roller from a photocopier.

I had to modify the pivot point on the drive frame, as the head of the bolt I was using fouled the bearing holder. I will remove it and paint it now that I have tested everything.

Hunting American dentists since 2015.