06-16-2013, 11:54 PM

There have been a number of posts on several different forums that show how to go about squaring up the base on a typical import 5-C "Spindexer" to the center line of it's bore. This makes it much easier to align the tool with the table travel of your machine. Or you can simply clamp it into your machine vice and be ready to go. (Assuming your vice is already indicated inline.)

Here is but one way of going about it, as an example:

http://www.modelenginemaker.com/index.php?topic=1427.0

This is only about how I went about setting up my own spindex in my mill to machine the sides of the base. Do a Google search and you'll find other ways of building a better mousetrap, I'm sure.

The painted sides of the base obviously need to go.

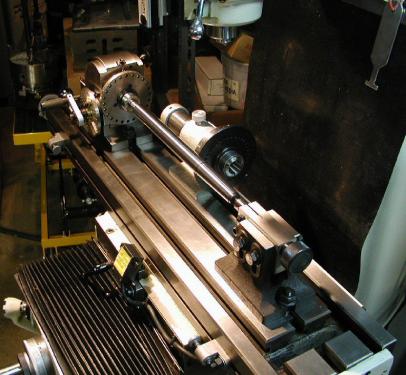

I mounted my ground lathe test bar between centers and adjusted it until a DTI showed no deflection in either the X or Z axis.

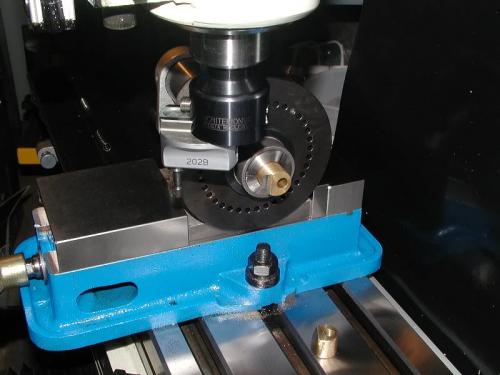

Then I removed the test bar from the centers and installed it in the spindex with the proper 5-C collet. I also made a bushing to fit between the back end of the test bar and the spindle bore to keep it centered. Put the bar and spindex back between the centers with the base plate UP.

I supported the body of the spindex with a machinist jack and leveled the bottom of the base before clamping it down. Run a DTI over the base plate until it shows level. That will keep the cuts on the sides of the base square to the bottom of the base. A few light cuts on the sides will remove the paint and Bondo and square them up to the bore center line.

I spent the greatest amount of time adjusting the screw jack and hold down clamps to get the base secured to the machine table without putting the spindex spindle in a bind. I had to keep going back and forth between the screw jack underneath and the two clamps above. A little too much pressure from any one of them and the spindle would start to bind. I just kept at it until everything was tight and the spindle turned freely. Another check with the DTI verified that the base remained level.

It turned out the bottom of the base and the front surface were already true to the spindle. The sides of the base were tapered however and had a lot more "Bondo" on them than I expected. After the layer of filler had been removed, the base was still wider at the front than in the rear. But after a few light cuts on the sides, a machinists square told me I was good to go. Good enough for Government work anyway, as they say.

An hour's worth of set-up time to make a couple of cuts that takes 5 minutes to do.

Here is but one way of going about it, as an example:

http://www.modelenginemaker.com/index.php?topic=1427.0

This is only about how I went about setting up my own spindex in my mill to machine the sides of the base. Do a Google search and you'll find other ways of building a better mousetrap, I'm sure.

The painted sides of the base obviously need to go.

I mounted my ground lathe test bar between centers and adjusted it until a DTI showed no deflection in either the X or Z axis.

Then I removed the test bar from the centers and installed it in the spindex with the proper 5-C collet. I also made a bushing to fit between the back end of the test bar and the spindle bore to keep it centered. Put the bar and spindex back between the centers with the base plate UP.

I supported the body of the spindex with a machinist jack and leveled the bottom of the base before clamping it down. Run a DTI over the base plate until it shows level. That will keep the cuts on the sides of the base square to the bottom of the base. A few light cuts on the sides will remove the paint and Bondo and square them up to the bore center line.

I spent the greatest amount of time adjusting the screw jack and hold down clamps to get the base secured to the machine table without putting the spindex spindle in a bind. I had to keep going back and forth between the screw jack underneath and the two clamps above. A little too much pressure from any one of them and the spindle would start to bind. I just kept at it until everything was tight and the spindle turned freely. Another check with the DTI verified that the base remained level.

It turned out the bottom of the base and the front surface were already true to the spindle. The sides of the base were tapered however and had a lot more "Bondo" on them than I expected. After the layer of filler had been removed, the base was still wider at the front than in the rear. But after a few light cuts on the sides, a machinists square told me I was good to go. Good enough for Government work anyway, as they say.

An hour's worth of set-up time to make a couple of cuts that takes 5 minutes to do.

Willie