02-22-2019, 05:01 AM

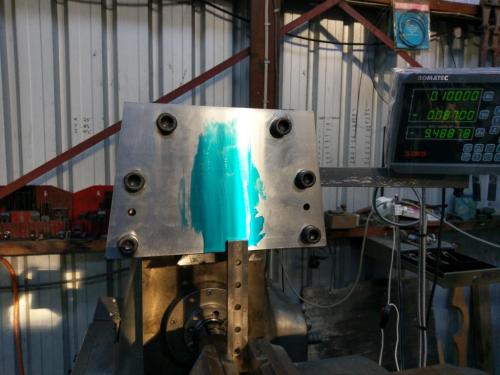

Got a few hours on the frankenmill yesterday and today. I ground both faces of the front plate on the surface grinder, had to take the back fence off the mag chuck and push the limits of how wide a piece the grinder can accommodate. The back edge of the plate contacted the column of the surface grinder with the front edge just behind the front face of the wheel. I do like a ground finish though.

I cleaned up the overarm ways and gib and used a wire wheel to get the layers of paint of the big adjusting screws, installed the overarm to the top of the mill and discovered that the bottom inside edge of one of the cheek plates fouled on the top of the machine so i couldn't slide the ram in.

Had to disassemble and trim the edge of the cheek plate with a file.

While the cheek plate was off, I took the opportunity to drill and tap the holes for the DRO display bracket. The two angle fixtures I made earlier in the build were at least useful for this.

Reassembled everything to the overarm and this time it slides in & out without any problems.

I used an edge finder to establish the centre line of the horizontal spindle, clamped a parallel upright in the vice and spent a bit of time making the parallel stand up dead straight. Found the edge, moved it in half the thickness of the edge finder then raised the knee to transfer the spindle center up to the to plate. This will result in the J-head spindle being in line with the horizontal spindle, not sure if that will ever matter bit it seems like a good idea.

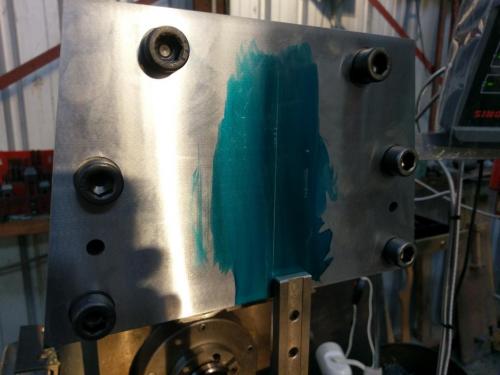

The DRO can be seen in the above photos, I think the location will work out well.

I cut a disc of coreflute to represent the size of the nose piece, to figure out the height I can place it to clear the existing bolts on the front plate. That enabled me to mark the centre of the nose piece, which will be spigoted onto the front plate and secured with a circle of bolts.

I'm having second thoughts about casting the nose piece, not sure that it would be wise for my first-ever iron casting to be such a critical component. I'll see how much of my hard-earned the steel merchants will sting me for a 75mm slug of 180mm diameter 4140.

I cleaned up the overarm ways and gib and used a wire wheel to get the layers of paint of the big adjusting screws, installed the overarm to the top of the mill and discovered that the bottom inside edge of one of the cheek plates fouled on the top of the machine so i couldn't slide the ram in.

Had to disassemble and trim the edge of the cheek plate with a file.

While the cheek plate was off, I took the opportunity to drill and tap the holes for the DRO display bracket. The two angle fixtures I made earlier in the build were at least useful for this.

Reassembled everything to the overarm and this time it slides in & out without any problems.

I used an edge finder to establish the centre line of the horizontal spindle, clamped a parallel upright in the vice and spent a bit of time making the parallel stand up dead straight. Found the edge, moved it in half the thickness of the edge finder then raised the knee to transfer the spindle center up to the to plate. This will result in the J-head spindle being in line with the horizontal spindle, not sure if that will ever matter bit it seems like a good idea.

The DRO can be seen in the above photos, I think the location will work out well.

I cut a disc of coreflute to represent the size of the nose piece, to figure out the height I can place it to clear the existing bolts on the front plate. That enabled me to mark the centre of the nose piece, which will be spigoted onto the front plate and secured with a circle of bolts.

I'm having second thoughts about casting the nose piece, not sure that it would be wise for my first-ever iron casting to be such a critical component. I'll see how much of my hard-earned the steel merchants will sting me for a 75mm slug of 180mm diameter 4140.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Milling Machine (n); a machine tool used in the production of lathe components.