Posts: 2,596

Threads: 99

Joined: Dec 2014

Location: Michigan

The following 2 users Like Vinny's post:

EdK (04-07-2015), Mayhem (04-07-2015)

I prefer the scrolls, change it back. :)

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

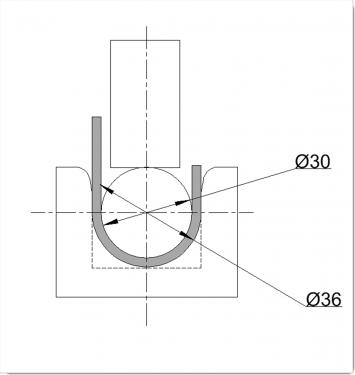

I thought as it was only 3mm thick it would deform reasonably easy, it don't

I spoke to a guy who does this "wrought iron" stuff - he suggested to heat it up (red) and do the scroll in one

quick go.

He said the knack to deforming stainless is to do it in one go and don't stop.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

I'm thinking of doing it in the 20 ton press - that should deform it.

It may need to have a round bottom, not flat as shown.

Might work - I have no idea how I end up doing all these "daft" things.

It will spring open quite a bit but I'll squash it in the vice

DaveH

.

. , anyway what CAD program are you using ?

, anyway what CAD program are you using ?  .

. , anyway what CAD program are you using ?

, anyway what CAD program are you using ?