04-08-2013, 05:27 PM

Still owe the board some shop photos which I will get round to but thought I'd show you a normal day or at least part of one.

Monday morning so as usual there is a job waiting on the yard outside the door when I get started.

As usual no instruction but there are two white marks on two diameters and quick check shows they are both undersize.

left hand one is 30mm for a bearing, right hand one is 25mm plus 0.01 for a brake hub.

So gob some snot on with the MiG and wait for it to dry.

Support with a steady and single point the centre hole in the end because they always bend a bit and turn down to finished sizes. Then replace the 8mm keyway.

Sorry for the crap photo must have tripped over something !

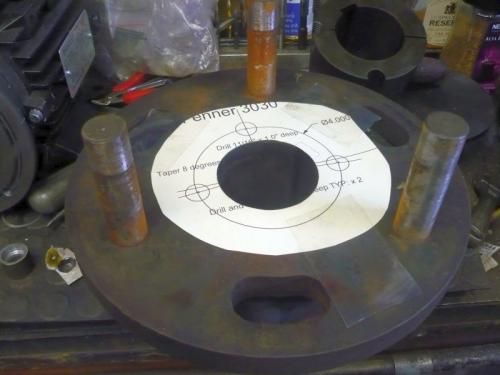

In the mean while a coupling I had been primed for on Friday appears, it's bored 70mm and keyed but is going onto a new motor at 65mm.

Always easier to go from 65 to 70 but going the other way requires boring out sleeving and pegging, then reboring and a new keyway cutting.

Or you could do as I do and cheat and fit a taper lock coupling. Hunt round on the CAD system and find the taperlock drawing and print out full size.

Hub, coupling and drawing.

Cut out on pre drawn 70mm circle and attach to hub with high precision sticky tape. Whack three mounting holes.

Drill two holes all the way thru and tap 5/8" Whit to suit supplied screws.

Drill last hole 5/8" clearance 1" deep for the extraction hole.

Stick in the lathe and bore out to the small taper end diameter, do this because I can use power feed and then do the last taper cut with the top slide set over to 4 degrees to open out to the final diameter.

Hole opened out at 4 degrees taper.

Ignore the rusty holes at 3 o,clock and 9 o,clock, they were already in but you see how the tapped holes have been half removes so the screws pushes the insert into the taper and causes it to grip the shaft.

Finished job.

I like taperlocks as they will take up slight wear on shafts and they really grip

Next job before dinner was a typical bodge.

Older Wadkin routers used to have 1 1/4" shafts but tooling for these is hard to find and inserted tooling is next to impossible, all modern tooling being on 30mm so Wadkins in their infinite wisdom just turned the 1 1/4" shafts down to 30mm but the 1 1/4" x 12 tpi thread then becomes half a thread.

No good them making a new shaft as their equipment of the era was all imperial and they couldn't screwcut metric [ or wouldn't ]

So they just cleaned the thread up and made a 30mm x 12 tpi nut to suit.

There are loads of these machines out there with double standard fittings, problem is Wadkin has gone to the wall and they never made any spare nuts anyway.

So cut the shaft down to 30mm and it shows the 1/2 thread that's left.

Make a new nut from a piece of hex bar, again bad pic.

Then pick the old thread up and cut a new thread to suit the nut.

And that's a typical morning, time for me cheese and pickle

Monday morning so as usual there is a job waiting on the yard outside the door when I get started.

As usual no instruction but there are two white marks on two diameters and quick check shows they are both undersize.

left hand one is 30mm for a bearing, right hand one is 25mm plus 0.01 for a brake hub.

So gob some snot on with the MiG and wait for it to dry.

Support with a steady and single point the centre hole in the end because they always bend a bit and turn down to finished sizes. Then replace the 8mm keyway.

Sorry for the crap photo must have tripped over something !

In the mean while a coupling I had been primed for on Friday appears, it's bored 70mm and keyed but is going onto a new motor at 65mm.

Always easier to go from 65 to 70 but going the other way requires boring out sleeving and pegging, then reboring and a new keyway cutting.

Or you could do as I do and cheat and fit a taper lock coupling. Hunt round on the CAD system and find the taperlock drawing and print out full size.

Hub, coupling and drawing.

Cut out on pre drawn 70mm circle and attach to hub with high precision sticky tape. Whack three mounting holes.

Drill two holes all the way thru and tap 5/8" Whit to suit supplied screws.

Drill last hole 5/8" clearance 1" deep for the extraction hole.

Stick in the lathe and bore out to the small taper end diameter, do this because I can use power feed and then do the last taper cut with the top slide set over to 4 degrees to open out to the final diameter.

Hole opened out at 4 degrees taper.

Ignore the rusty holes at 3 o,clock and 9 o,clock, they were already in but you see how the tapped holes have been half removes so the screws pushes the insert into the taper and causes it to grip the shaft.

Finished job.

I like taperlocks as they will take up slight wear on shafts and they really grip

Next job before dinner was a typical bodge.

Older Wadkin routers used to have 1 1/4" shafts but tooling for these is hard to find and inserted tooling is next to impossible, all modern tooling being on 30mm so Wadkins in their infinite wisdom just turned the 1 1/4" shafts down to 30mm but the 1 1/4" x 12 tpi thread then becomes half a thread.

No good them making a new shaft as their equipment of the era was all imperial and they couldn't screwcut metric [ or wouldn't ]

So they just cleaned the thread up and made a 30mm x 12 tpi nut to suit.

There are loads of these machines out there with double standard fittings, problem is Wadkin has gone to the wall and they never made any spare nuts anyway.

So cut the shaft down to 30mm and it shows the 1/2 thread that's left.

Make a new nut from a piece of hex bar, again bad pic.

Then pick the old thread up and cut a new thread to suit the nut.

And that's a typical morning, time for me cheese and pickle

John S., Nottingham, England.