07-17-2013, 06:57 PM

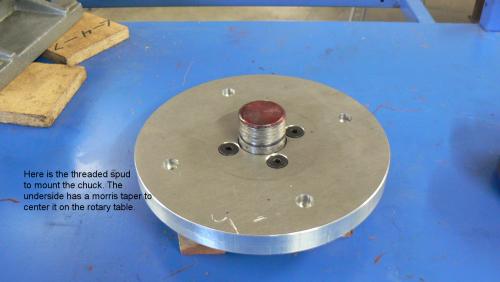

Last month I purchased a rotary table and tail-stock combination from ENCO while they were having a sale. They shipped me a Phase II table and tali-stock that will help round out the capabilities of my vertical mill. Now every rotary table needs an adapter to be able to mount a three jaw chuck, so the first project was to make one using the table. The three jaw chuck I used was one I had from my Craftsman 12" lathe. The chuck dates back to 1916 and it still is functioning. I purchased a scrap of aluminum, from my local supplier and went to work. The design is simple but functional. Here are some pictures of how it turned out. This was my first attempt to cut 6 pitch threads and my first attempt to turn a Morris taper. Here are some pictures of the adapter.

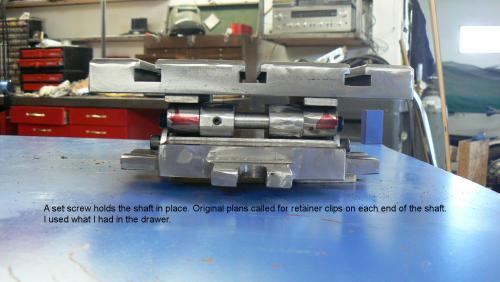

My next project was to make a tilting table. One day I was cursing this site and got a link to the Home Metal Shop Club in Texas. On their site they had a set of plans for a tilting table that were published in their newsletter back in June 2011. The table was designed by Dick Kosteinicek and he produced a complete set of drawings. Well I took a little poetic licence and adapted his plans to the material I had and my skill level as a machinist and here is the table. The material bill was about $70.00 and the additional tooling I had to purchase ran about $150.00 for slot cutters and counter boars, and taps.

My next project was to make a tilting table. One day I was cursing this site and got a link to the Home Metal Shop Club in Texas. On their site they had a set of plans for a tilting table that were published in their newsletter back in June 2011. The table was designed by Dick Kosteinicek and he produced a complete set of drawings. Well I took a little poetic licence and adapted his plans to the material I had and my skill level as a machinist and here is the table. The material bill was about $70.00 and the additional tooling I had to purchase ran about $150.00 for slot cutters and counter boars, and taps.

ml_woy, proud to be a member of MetalworkingFun since Jul 2012.

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)