Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

Jerry,

Unfortunately, there is no "I think it has an oil leak!" about it. I KNOW it has an oil leaks since it's been leaking for a couple of years now. And no , this is definitely not "Too much fun!". I'd much rather be making chips then getting my hands soiled with the unknown substance the manufacturer used to lubricate this machine with.

Ed

Posts: 168

Threads: 6

Joined: Mar 2012

Location: Surrey, England

HI Ed, great write-up so far!

You may find that an ER collet nut wrench fits the bearing locknut... It does on a lot of the smaller RF mills and clones, I know because I've used them for the job!

The ER32 or ER40 wrench may just fit that nut, if so next question: How are you going to hold the shaft to get it off? The smaller mills often have a slot for a tommy bar - beware though, the slot's usually in a piece of Chinese top-quality hardened putty, so make sure the bar's a *good* fit or be prepared to do some tidying up with file and stones afterwards...

Dave H. (the other one)

Rules are for the obedience of fools, and the guidance of wise men...

(Douglas Bader)

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(03-22-2012, 06:37 PM)Hopefuldave Wrote: HI Ed, great write-up so far!

You may find that an ER collet nut wrench fits the bearing locknut... It does on a lot of the smaller RF mills and clones, I know because I've used them for the job!

The ER32 or ER40 wrench may just fit that nut, if so next question: How are you going to hold the shaft to get it off? The smaller mills often have a slot for a tommy bar - beware though, the slot's usually in a piece of Chinese top-quality hardened putty, so make sure the bar's a *good* fit or be prepared to do some tidying up with file and stones afterwards...

Dave H. (the other one)

Hi Dave,

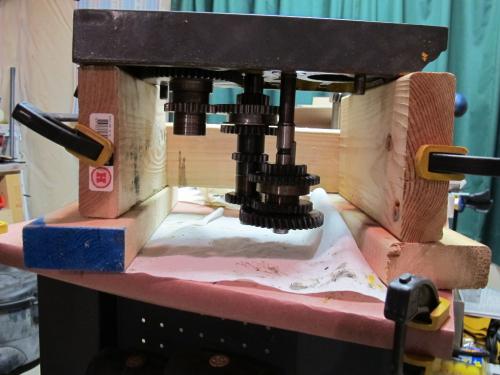

Unfortunately my collet chuck did not come with a wrench. I had started making a similar wrench for my 9x20 lathe some time back but got rid of the lathe so the wrench never got finished. Well it did today and I made use of it.

I tried holding it with my gloved hand and striking the wrench with a dead blow hammer but that didn't work. Then I realized I had a wrench for holding the spindle while tightening the draw-bar. It worked like a champ.

Ed