Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

The following 1 user Likes oldgoaly's post:

DaveH (09-02-2013)

When I bought much of my foundry tools a Mini-Mote muller was part of the deal, it needed work, coupler was loose, scraper arm broken, but for the 60$ bucks I gave for all of them, the molding bench, 4 aluminum flasks, B16 crucible furnace, misc tools, I'm not going to complain!

Now this does about enough sand for a cope or drag 12 by 12 by 4 flask.

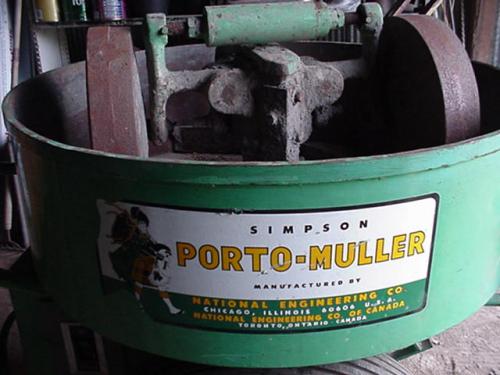

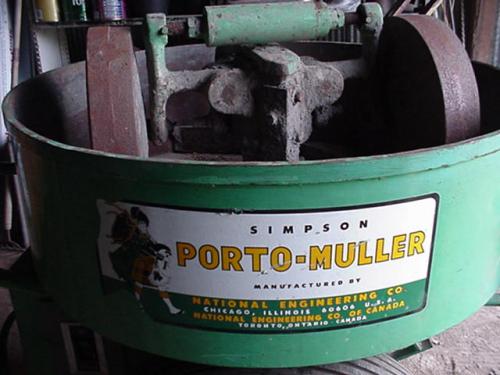

Years later I came across the Simpson, on of the guys on the yahoogroup Micheal Boettiker (sp?) found it thru the Wisconsin state school surplus. So I went up to Madison and paid him for the muller, then drove 7 hours hoe happy as can be. It had been reduced to 250 was 300, I gave Mike the 300! Here is some pics of it as we unloaded it and in action this does 3 full flasks, but that is at the limit of the VFD driving the 3 hp motor.

I like my mixer (hf) for adding oil to rejuvenate the petrobond sand,but the muller is so much better reworking the sand in between uses that is for another post.

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

Well the mixer actually came from Bucheit's a farm and home store about 50 miles from here a Clarke brand the same basic mixer as harbour freight sells.

When I got the foundry stuff, the sand was dry! so scrounged around and traded for some real petrobond oil, before I used it all I did as much comparing as I could to other common oils and the 2 stroke engine oil is similar. I've had to add oil to about every two years or so, with out a problem. I find if the mixer is almost horizontal not to full the mixing action is at it's best. If one was to make a cover for the opening you could put more in, but if your making molds it just go about your way it will be ready in a 20 minutes or so. In the "Hot Shop" there is a crushed limestone floor so dropping sand on the floor is wasting it, so I try to limit the waste.

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

DA,

don't know if you can see it on the Simpson the nubs are still on the tires, belt is like brand new, gear lube was like new. This was used in the agricultural dept? I took sand blast sand and mulled it to clean it out. I don't have a good pic of the "baby moons" on it!

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 184

Threads: 21

Joined: Feb 2013

Location: north yorkshire n.e.england

(08-30-2013, 04:45 PM)oldgoaly Wrote: When I bought much of my foundry tools a Mini-Mote muller was part of the deal, it needed work, coupler was loose, scraper arm broken, but for the 60$ bucks I gave for all of them, the molding bench, 4 aluminum flasks, B16 crucible furnace, misc tools, I'm not going to complain!

Now this does about enough sand for a cope or drag 12 by 12 by 4 flask.

Years later I came across the Simpson, on of the guys on the yahoogroup Micheal Boettiker (sp?) found it thru the Wisconsin state school surplus. So I went up to Madison and paid him for the muller, then drove 7 hours hoe happy as can be. It had been reduced to 250 was 300, I gave Mike the 300! Here is some pics of it as we unloaded it and in action this does 3 full flasks, but that is at the limit of the VFD driving the 3 hp motor.

I like my mixer (hf) for adding oil to rejuvenate the petrobond sand,but the muller is so much better reworking the sand in between uses that is for another post.

Bl**dy hell that's a whopper, sure makes my little mixer look tame,still it does all my requirements!! What I'd like to ask you is what's this oil you use to rejuvinate petrobond? I've seen it mentioned a few times before but only in america, when I use petrobond [reserved for fine castings 'cos of the cost] I carefully scrape all the burnt stuff from the casting & discard it so it doesn't reduce the bond quality of the rest of the sand,do you mix all the burnt stuff back in then add some kind of ''rejuvinating oil''?? if so what's it called & where do you get it?? cheers

Graham.

the artfull-codger, proud to be a member of MetalworkingFun Forum since Feb 2013.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

I know I'm going to catch hell for this but I use 30 wt non detergent motor oil, I know they sell some high dollar stuff but all you really need is a low ash content oil.

and I'll put my oil bonded sand up against anyones, and I been dumping the same stuff back in the muller for almost two years with a small addition of petrobond powder every year or so.

DA

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

Graham

I'll get you the details after it cools down some, 99 degree here that is in the shade!

I bought a few cases of Texaco two stroke oil for using in my chainsaw, weed wackers, and a Villier's motor or two in a few old British lightweights! I grew up in a town called Belleville, Illinois there were 20 foundries at least maybe one or 2 left? They use oil-boded sand and it is black! in fact I think it works better when aged! My experience with new sand is from the local Jr College sand casting class about 15 years of going. every 2-3 years they would swap the old sand out for new, (I would get some of the used sand each time) Basically we would mix up "ovaline" brand sand, box of petro-bond "dirt" and a small amount of PB oil. Remember we are limited by our mixer! which there was drywaller's mud mixer ( paddle type mixer) so we are making 100 lbs at a time There is a activator for PB, I've been told it is a alcohol based product. Jim Barnes got it online? he gave it to me when he moved, he is a local guy, We tried many times to have monthly casting days even yearly get togethers but stuff happens!

My green sand experience is more limited, but the only real difference is water evaporates and is boiled off easier than oil, the size of the grains of sand is going to play a bigger part of your parts finish than oil or water do.

One other thing I have noticed, I now have all my sand in metal or metal lined containers, it has not dried out as fast!

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

That is the stuff! I must have thrown out the old can of the PB oil, I put the PB rejuvenating powder in a old coffee container, the plastic bag and box are gone. (why I never throw anything away cough)

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 184

Threads: 21

Joined: Feb 2013

Location: north yorkshire n.e.england

The following 1 user Likes the artfull-codger's post:

oldgoaly (09-01-2013)

(08-31-2013, 03:51 PM)oldgoaly Wrote: Graham

I'll get you the details after it cools down some, 99 degree here that is in the shade!

I bought a few cases of Texaco two stroke oil for using in my chainsaw, weed wackers, and a Villier's motor or two in a few old British lightweights! I grew up in a town called Belleville, Illinois there were 20 foundries at least maybe one or 2 left? They use oil-boded sand and it is black! in fact I think it works better when aged! My experience with new sand is from the local Jr College sand casting class about 15 years of going. every 2-3 years they would swap the old sand out for new, (I would get some of the used sand each time) Basically we would mix up "ovaline" brand sand, box of petro-bond "dirt" and a small amount of PB oil. Remember we are limited by our mixer! which there was drywaller's mud mixer ( paddle type mixer) so we are making 100 lbs at a time There is a activator for PB, I've been told it is a alcohol based product. Jim Barnes got it online? he gave it to me when he moved, he is a local guy, We tried many times to have monthly casting days even yearly get togethers but stuff happens!

My green sand experience is more limited, but the only real difference is water evaporates and is boiled off easier than oil, the size of the grains of sand is going to play a bigger part of your parts finish than oil or water do.

One other thing I have noticed, I now have all my sand in metal or metal lined containers, it has not dried out as fast!

Thanks for that info ''oldgoaly'' yes greensand & boiling hot sunny days don't make good bedmates!! [wish it was that warm over here!!]

Graham.

the artfull-codger, proud to be a member of MetalworkingFun Forum since Feb 2013.

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

|