Posts: 375

Threads: 53

Joined: Jun 2013

Location: Jonesborough, TN

I'm setting up my foundry almost from scratch. A friend is helping me make a Vontorne muller. Now I need a molding bench and want to get it built before the muller is available. Are there any good molding bench plans available? I will be using green sand to start.

I have a couple ideas but want to ask the experienced to avoid design errors. What plans did you build from? I need to know basic dimensions and useful features. I'm thinking 24" x 48" and 12-24" deep, slats on top for holding flasks, room underneath for tubs to hold new/mulled sand.

Is 1/2" plywood strong enough or should I go with 3/4"? Should I divide it into 2 sections for conditioned vs. used sand?

Show us pictures of your molding bench, any special features, why you like/dislike your bench.

Thanks in advance.

Chuck

Micromark 7x14 Lathe, X2 Mill , old Green 4x6 bandsaw

The difficult takes me a while, the impossible takes a little longer.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

Great timing on this question Chuck.

I don't have the answers but am approaching the same position as you once the foundry/ blacksmith shop/ welding area is finished.

Does your friend or you have plans for the muller?

Free advice is worth exactly what you payed for it.

Greg

Posts: 375

Threads: 53

Joined: Jun 2013

Location: Jonesborough, TN

(09-25-2013, 07:22 PM)f350ca Wrote: Great timing on this question Chuck.

I don't have the answers but am approaching the same position as you once the foundry/ blacksmith shop/ welding area is finished.

Does your friend or you have plans for the muller?

We are building the George Vontorne Muller. Just Google Vontorne and you should find a .pdf with the instructions to build it. My friend has all the equipment, plasma, welders, grinders, etc. I provided the propane tanks.

Let me know if you don't find the plans and I'll get you a link or send you a copy.

Chuck

Micromark 7x14 Lathe, X2 Mill , old Green 4x6 bandsaw

The difficult takes me a while, the impossible takes a little longer.

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

Chuck my old molding bench is made from a cabinet from a science lab, you probably seen them, what I did was line it with metal, 26 gauge cause it doesn't need to be to thick. then used 2 by 2 for the slats. My newer bench is a mifco that was missing a door, I just made a 26 gauge one to keep the cat or mice out. If you would like pics just ask I'll be happy to post them.

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 375

Threads: 53

Joined: Jun 2013

Location: Jonesborough, TN

(09-25-2013, 07:51 PM)oldgoaly Wrote: Chuck my old molding bench is made from a cabinet from a science lab, you probably seen them, what I did was line it with metal, 26 gauge cause it doesn't need to be to thick. then used 2 by 2 for the slats. My newer bench is a mifco that was missing a door, I just made a 26 gauge one to keep the cat or mice out. If you would like pics just ask I'll be happy to post them.

oldgoaly, what are the dimentions of your bench? Are you happy with it? What would you do different. And lastly, do you keep used sand separate from the conditioned sand?

Chuck

Micromark 7x14 Lathe, X2 Mill , old Green 4x6 bandsaw

The difficult takes me a while, the impossible takes a little longer.

Posts: 251

Threads: 21

Joined: Jun 2013

Location: Shiloh, Il. USA

09-25-2013, 08:13 PM

(This post was last modified: 09-25-2013, 08:14 PM by oldgoaly.)

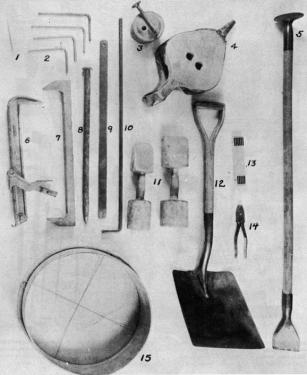

old one is 3' by 3' the mifco is 3' by 6' (rough dimensions) , sand goes from mold bench to mold to pour to break down box to muller to mold bench always in the circle none is sitting idle. All my sand is used and I am using oil bond sand that should be kept in a closed metal container. a rough guess on how much sand is about 400 pounds. As for as liking the bigger is better! the small one needs a table next to it to hold the other 1/2 of mold, plus it is taller. how big of molds do you want to make my big flask is 12 by 18. Btw I use a small coal shovel to fill my molds, a good amount for the hand riddle. the rest of the sand gets moved by a foundry shovel see #12 on pic.

oldgoaly, proud to be a member of MetalworkingFun Forum since Jun 2013.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

Found them, thanks Chuck

Free advice is worth exactly what you payed for it.

Greg

Posts: 375

Threads: 53

Joined: Jun 2013

Location: Jonesborough, TN

Oldgoaly,

I don't know how big I'll end up going, but I am starting small. I want to start with aluminum parts for small engines and such. Maybe progress to brass/bronze. I have built 1 flask, 12" x 12". That should keep me busy for a while.

Chuck

Micromark 7x14 Lathe, X2 Mill , old Green 4x6 bandsaw

The difficult takes me a while, the impossible takes a little longer.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

make your bench the minimum of 24 wide X 48 long, and whatever is comfortable for you to stand at not all people are the same height. and make it strong as and ox, remember that your going to be pounding sand on it, fix it so the molding board can slide from side to side and that the tub or tubs can be tilted out to either shovel the sand into or back out of the tub's.

the top should be so that you can use a scoop to reach into the tubs to get sand for the mold which will stop sand spillage, you also need a back splash with places for tools and such.

remember 2X4 construction is probably the cheapest and strongest way to go.

Your sand will last a looooong time with additions of bentonite to it every now and then so that it will stick together. some places you can find good casting sand in your yard that doesn't need anything added to it.

your 12 X 12 flask if its like 3.5 inches deep is going to take about forty pounds of sand to fill each half depending on the pattern in it.

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 375

Threads: 53

Joined: Jun 2013

Location: Jonesborough, TN

Thanks for your comments, dallen. That's the basic design I've chosen. Do you use greensand or petrobond sand? How hard is it to control moisture in green sand? I'm thinking of using plastic storeage bins for the sand that have covers. I see a lot of molding benches use cement mixing tubs for the sand. Will they be suficient to keep the moisture level controlled, or do they need to be covered?

Chuck

Micromark 7x14 Lathe, X2 Mill , old Green 4x6 bandsaw

The difficult takes me a while, the impossible takes a little longer.

|