Posts: 531

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The following 1 user Likes Hawkeye's post:

how'sitwork? (05-06-2015)

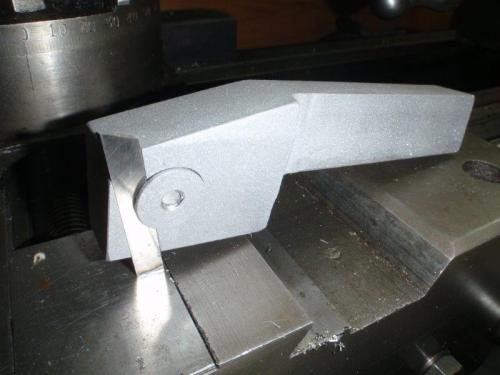

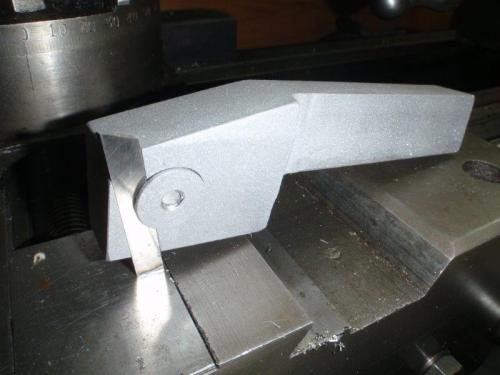

I use my tangential toolholder on the 9" lathe so much that I had to make one to fit the big Storebro lathe. It was already on the list, but Arbelist happened to post a few pics of his on my thread on a Centre Gauge. Very similar to what I had in mind. Really good timing. I borrowed a couple of ideas from him.

I opted for a 5/16" HSS cutter, so I used a 1/4" endmill to cut the groove. It's set at 12* left and 12* forward. When I first got into this hobby, I assumed that if you wanted a 5/16" groove, you would use a 5/16" endmill. If you do, you get a sloppy, oversized groove as the bit pulls off to one side. By cutting a narrower groove down the middle and then cutting to the line on each side, you get a truer groove with more control.

A perfect slip fit.

When I made the first tangential, I also made a fixture to grind the cutter to the required 30* angle.

A double counterbore to make room for the clamp. I copied Arbelist's clamp - works very well.

You can see the 12 x 12 angles on the cutter.

The other idea I borrowed from Arbelist was to blast the holder with crushed glass. Gives it a nice finish.

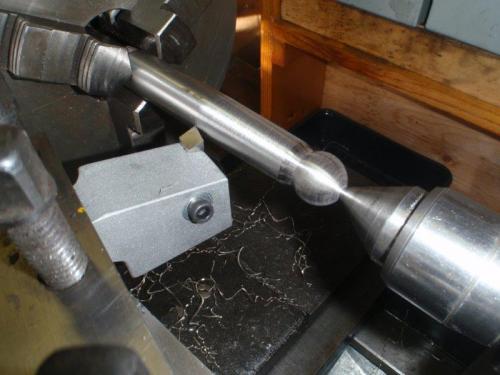

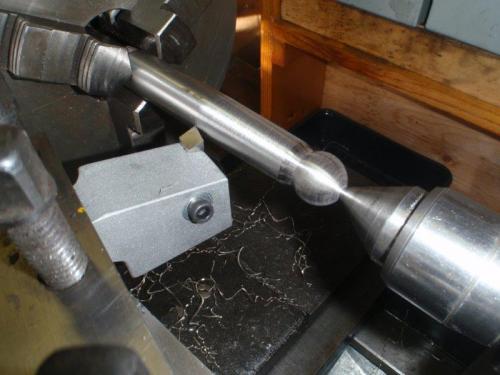

Tangential toolholders do a great job in both turning and facing operations.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 175

Threads: 4

Joined: Sep 2012

Location: Dorset, UK

The following 1 user Likes Arbalest's post:

how'sitwork? (05-06-2015)

12-25-2013, 05:58 AM

(This post was last modified: 12-25-2013, 06:01 AM by Arbalest.)

Nice work Mike, that holder looks good! Might be an idea to wipe some oil or wax on it to stop it rusting, that's what I do.

This is my grinding jig, the strap stops me burning my fingers!

![[Image: IMGP1688_zps994912ea.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP1688_zps994912ea.jpg)

Arbalest, proud to be a member of MetalworkingFun since Sep 2012.

Posts: 3,795

Threads: 183

Joined: Jun 2012

Location: Farmington Hills, Michigan

Nice job Mike, I've been meaning to try one of these tangential holders. Does it have a side cutting edge angle built in as well, or do you just angle the shank?

Coincidentally, I just posted the first project tutorial videos for a lathe carriage stop and milling a slot like the one for your tool bit was one of the operations covered. I position a smaller end mill on the center of the slot and zero my dials or the DRO, subtract the diameter of the end mill from the slot width and divide by two. That holds position of the slot and gives me a good idea of how much material needs to be removed in each direction. On larger slots, an adjustable parallel makes short work of measuring the slot width.

Tom

Posts: 531

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

Tom, the bit is angled toward the work and toward the headstock. Both angles are typically 12*. Only the end of the tool blank is ground, at an angle of 30* diagonally. The effect of the combination of angles is a diamond with a narrow angle of about 85*.

If you set it up right, you can do both turning and facing operations without rotating the toolholder. It's a good idea to hone the long corner, the cutting corner, to a small radius, as with other types of cutters.

These things work so well that it's worth making one just to try it out.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 175

Threads: 4

Joined: Sep 2012

Location: Dorset, UK

I need to make a right hand version as well!

Arbalest, proud to be a member of MetalworkingFun since Sep 2012.

Posts: 184

Threads: 21

Joined: Feb 2013

Location: north yorkshire n.e.england

(12-25-2013, 12:42 AM)Hawkeye Wrote: I use my tangential toolholder on the 9" lathe so much that I had to make one to fit the big Storebro lathe. It was already on the list, but Arbelist happened to post a few pics of his on my thread on a Centre Gauge. Very similar to what I had in mind. Really good timing. I borrowed a couple of ideas from him.

I opted for a 5/16" HSS cutter, so I used a 1/4" endmill to cut the groove. It's set at 12* left and 12* forward. When I first got into this hobby, I assumed that if you wanted a 5/16" groove, you would use a 5/16" endmill. If you do, you get a sloppy, oversized groove as the bit pulls off to one side. By cutting a narrower groove down the middle and then cutting to the line on each side, you get a truer groove with more control.

A perfect slip fit.

nice one Mike, might knock one up myself,I bought one[cheated!!] from eccentric engineering a few years ago & love it, dead easy to keep sharp & cheap tool bits from autojumbles.

When I made the first tangential, I also made a fixture to grind the cutter to the required 30* angle.

A double counterbore to make room for the clamp. I copied Arbelist's clamp - works very well.

You can see the 12 x 12 angles on the cutter.

The other idea I borrowed from Arbelist was to blast the holder with crushed glass. Gives it a nice finish.

Tangential toolholders do a great job in both turning and facing operations.

the artfull-codger, proud to be a member of MetalworkingFun Forum since Feb 2013.

Posts: 175

Threads: 4

Joined: Sep 2012

Location: Dorset, UK

Apart from the negligible "running" cost of Tangential tool holders (HSS is cheap) what I really like is the very quick and easy height setting - once you've made a gauge for your Lathe.

![[Image: IMGP1776_zps979b8685.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP1776_zps979b8685.jpg)

Arbalest, proud to be a member of MetalworkingFun since Sep 2012.

Posts: 184

Threads: 21

Joined: Feb 2013

Location: north yorkshire n.e.england

12-27-2013, 06:15 AM

(This post was last modified: 12-27-2013, 10:00 AM by EdK.)

(12-27-2013, 04:45 AM)Arbalest Wrote: Apart from the negligible "running" cost of Tangential tool holders (HSS is cheap) what I really like is the very quick and easy height setting - once you've made a gauge for your Lathe.

![[Image: IMGP1776_zps979b8685.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP1776_zps979b8685.jpg)

WOW arbalest that's a usefull height setting ![[Image: 6799.gif]](http://www.metalworkingfun.com/images/smilies/6799.gif) gauge it's much better than mine,I'm afraid I'm going to copy that .thank's for the design!!

Graham

the artfull-codger, proud to be a member of MetalworkingFun Forum since Feb 2013.

Posts: 175

Threads: 4

Joined: Sep 2012

Location: Dorset, UK

12-27-2013, 06:37 AM

(This post was last modified: 12-27-2013, 10:48 AM by Arbalest.)

Glad you liked it Graham. It's takes a little care to get it spot-on but once made saves a lot of time.

You might want to recess the base a little to help ensure it stands flat:

![[Image: IMGP2128_zpsfcbd6207.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP2128_zpsfcbd6207.jpg)

Arbalest, proud to be a member of MetalworkingFun since Sep 2012.

Posts: 531

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

I suppose you could make it like a machinist's jack, with the underside of the bolt head trued up and a good jam nut to lock it. That would make the initial setup a bit easier.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

|

![[Image: IMGP1688_zps994912ea.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP1688_zps994912ea.jpg)

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)

![[Image: IMGP1776_zps979b8685.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP1776_zps979b8685.jpg)

![[Image: 6799.gif]](http://www.metalworkingfun.com/images/smilies/6799.gif) gauge it's much better than mine,I'm afraid I'm going to copy that .thank's for the design!!

gauge it's much better than mine,I'm afraid I'm going to copy that .thank's for the design!!![[Image: IMGP2128_zpsfcbd6207.jpg]](http://i230.photobucket.com/albums/ee286/Arbalist/IMGP2128_zpsfcbd6207.jpg)