Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

I'd be interested in hearing how they work. Have thought about buying a set. In the past I've turned a shaft to the size I need, drill and thread the end for a pipe plug then split it on the band saw.

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

I've decided not to use the expanding arbor. Instead I'm going to bore the hole to size and then make an arbor to match the bore. I'll tap a hole for a bolt in the end of the arbor to hold the piece on. That's how I've done it in the past and it's worked well.

Ed

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

What a stringy mess. My lathe is so dirty I'm ashamed to take a picture of it. Anyway, I got some more done on the power feed today.

Ed

The stringy mess.

The culprit.

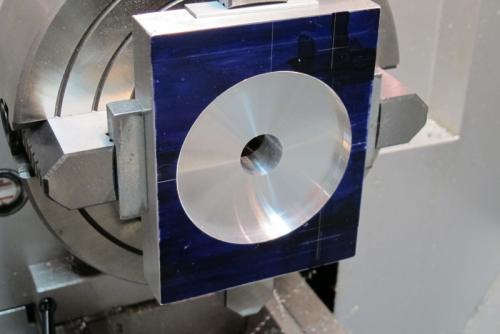

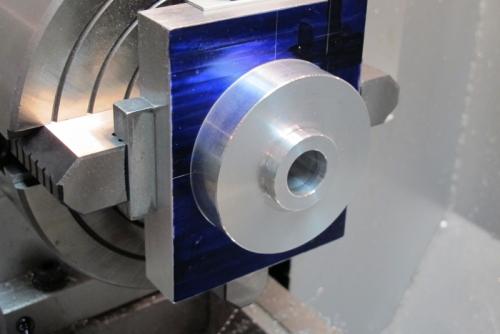

The result, a nice fit.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

Ya, if my lathe ever got that dirty I'd never take a photo either.

Nice machining by the way.

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(02-01-2015, 05:42 PM)f350ca Wrote: Ya, if my lathe ever got that dirty I'd never take a photo either.

...

Ed

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

You guys should be ashamed when you have a CLEAN machine, not a dirty one!

Ed, why are there blocks between the work piece and the chuck jaws rather than just copper or brass shims? Did you need the back of the part clear for a big through hole or something?

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(02-01-2015, 08:15 PM)PixMan Wrote: You guys should be ashamed when you have a CLEAN machine, not a dirty one!

guilty as charged.

(02-01-2015, 08:15 PM)PixMan Wrote: Ed, why are there blocks between the work piece and the chuck jaws rather than just copper or brass shims? Did you need the back of the part clear for a big through hole or something?

The opposing jaws wouldn't close enough to clamp the part, they ran into the other jaws, so I had to add some packing material.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

you could turn those two around

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!