Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(08-13-2015, 09:48 AM)Sunset Machine Wrote: I'll be making a Mayhem forge! Right now it all goes into a hibachi (barbeque)...

(08-13-2015, 12:09 PM)EdK Wrote: I like your forge Darren. I think I just may copy it. It's small enough so as to not take up a lot of room.

Thanks guys - I thought that I had posted a build thread on this but a search of the welding and casting proved otherwise. If you would like I can put together a post.

Hunting American dentists since 2015.

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(08-14-2015, 07:15 AM)Mayhem Wrote: (08-13-2015, 09:48 AM)Sunset Machine Wrote: I'll be making a Mayhem forge! Right now it all goes into a hibachi (barbeque)...

(08-13-2015, 12:09 PM)EdK Wrote: I like your forge Darren. I think I just may copy it. It's small enough so as to not take up a lot of room.

Thanks guys - I thought that I had posted a build thread on this but a search of the welding and casting proved otherwise. If you would like I can put together a post.

Yes, please post about it. I need to make drawings.

Ed

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

EdK (08-14-2015)

(08-14-2015, 07:19 AM)EdK Wrote: Yes, please post about it. I need to make drawings.

Ed

No drawings needed Ed, unless you are using AmishCad. This is a classic make it up as you go along project!

Hunting American dentists since 2015.

Posts: 258

Threads: 30

Joined: May 2015

Location: NJ

The following 1 user Likes Kennyv's post:

DaveH (08-14-2015)

Nice work Rob Btw im new here so have never seen your work .. absolutely gorgeous . Pure craftsmanship......if I can ask are ya still working and can what do ya do for a living ?

Also what type of surface finish are you putting on the tools blasting /etching . can ya briefly explain the process . Very nice

thanks

(08-14-2015, 12:21 PM)Kennyv Wrote: Nice work Rob Btw im new here so have never seen your work .. absolutely gorgeous . Pure craftsmanship......if I can ask are ya still working and can what do ya do for a living ?

Also what type of surface finish are you putting on the tools blasting /etching . can ya briefly explain the process . Very nice

thanks

Hi and thanks Kenny ,

Yes still working unfortunately ,still got 20 years to do (just a young lad ) ,,,,,,,,,,,,,,, I am a florist LOL ,,,,,,,,,,,,,, narh just joking at present I repair material handling and access equipment , forklifts, cranes and cherry pickers that sort of gear .

As for surface finish ,,,,,,,,,, anything from oh natural , plating , anodizing and other oxide coatings , I do like messing with electro chemistry and the tooling shown previous have just been used as test beds to see how things work/stand the test of time . Anyway way to big of a subject to be discussed in this thread , maybe in a separate thread .

May as well add the instrument makers vices to the post ,,,,,,,,,,,,,,,,,,,,,,,,even though they have been seen before .

![[Image: P1060337_zps162270a3.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060337_zps162270a3.jpg)

![[Image: P1060346_zps83c77575.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060346_zps83c77575.jpg)

![[Image: P1060314_zpsbmcdxl7g.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060314_zpsbmcdxl7g.jpg)

![[Image: P1060371_zpsqrokv7zh.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060371_zpsqrokv7zh.jpg)

![[Image: P1060350_zps16d5d4c7.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060350_zps16d5d4c7.jpg)

OH natural finish

Cheers Rob

RobWilson

Unregistered

The following 3 users Like RobWilson's post:

Kennyv (08-15-2015), Highpower (08-16-2015), aRM (08-24-2015)

OK last tool/attachment ,,,,,,,,,,,,,,,,,,,,,,,,, its getting boring looking at my own work , one thousand plus members and only a hand full of lads making there own tools ,,,,,,,,,,, whats everyone else doing,,,,,, armchair engineering, or getting UPS to deliver them .

Tapper turning attachment for the Myford Super 7 lathe .

![[Image: PB220159_zpsmnrnzvg6.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB220159_zpsmnrnzvg6.jpg)

![[Image: PB220158_zpst9lws133.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB220158_zpst9lws133.jpg)

![[Image: PB010126_zps4mjavtgt.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB010126_zps4mjavtgt.jpg)

![[Image: PA300137_zpsgr9yuzps.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PA300137_zpsgr9yuzps.jpg)

![[Image: PC070184_zpsni6s8s1m.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC070184_zpsni6s8s1m.jpg)

![[Image: PB060143_zpsnraur33b.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB060143_zpsnraur33b.jpg)

![[Image: PB060145_zpsmkdbaniy.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB060145_zpsmkdbaniy.jpg)

![[Image: PB070144_zps9u5wugwg.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB070144_zps9u5wugwg.jpg)

![[Image: PB280170_zps3havbcbd.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB280170_zps3havbcbd.jpg)

![[Image: PB280172_zpsewy8g8fi.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB280172_zpsewy8g8fi.jpg)

![[Image: PC060172_zpsv8tc3rum.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC060172_zpsv8tc3rum.jpg)

![[Image: PC060174_zps2djgmlg8.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC060174_zps2djgmlg8.jpg)

![[Image: PC060175_zps5fmouua6.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC060175_zps5fmouua6.jpg)

I lost the photos of it attached to the lathe when new , so these will have to do .

![[Image: P10105681_zpsh7hiji4l.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/P10105681_zpsh7hiji4l.jpg)

![[Image: P1060515_zps2gccgwly.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/P1060515_zps2gccgwly.jpg)

Rob

Posts: 684

Threads: 42

Joined: Mar 2012

Location: Rochester, NY

The following 1 user Likes rleete's post:

Bigtrev (12-19-2016)

Hard act to follow, but I will anyway.

Called a "nudger" by Bogstandard, who first posted it over on that other forum. Made a set, thinking it was something to do, but I'd never use it. Turns out, I use it almost every time I chuck something up in the lathe. Makes getting parts running true much easier.

Full of ideas, but slow to produce parts

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

Wow Rob! That taper attachment is really nice. I assume there was some welding involved in making it, correct?

Gorgeous as usual.

Ed

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Highpower (08-16-2015)

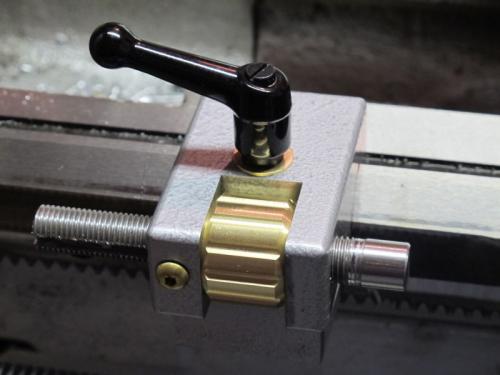

Here's the carriage stop I made for the lathe. I've got a Mark II in the works to fix some of the issues with this one though. This one will get relegated to holding a dial indicator once the Mark II is done.

Ed

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 1 user Likes f350ca's post:

Highpower (08-16-2015)

Your a tough act to follow Rob

A tool post and height gauge I made. In my infinite wisdom its not standard sized so I have to make my own holders.

![[Image: IMG_1107.jpg]](https://lh3.googleusercontent.com/-DNzOrZQnRaI/UzS66J9-SvI/AAAAAAAACA4/Odr7WfzaCOI/s1280-Ic42/IMG_1107.jpg)

Die holders for the lathe

![[Image: IMGP1183.jpg]](https://lh3.googleusercontent.com/-c1B5NjQV2kw/S6EYuET0XRI/AAAAAAAAAGc/k65JNQAqmtA/s1024-Ic42/IMGP1183.jpg)

Sand blast cabinet, the panels are plastic used for the boards in an ice rink.

![[Image: IMGP1252.jpg]](https://lh3.googleusercontent.com/-YMUxXTemdV8/S7vu0FDhg2I/AAAAAAAAAHM/iINZQ4bwAAU/s1440-Ic42/IMGP1252.jpg)

A plate roller, I've rolled 5/16 plate 12 inches wide with no problems.

![[Image: IMG_0883.jpg]](https://lh3.googleusercontent.com/-_YPlrR6j280/Upf1-pRGALI/AAAAAAAABr4/scsgGN4RPuM/s1280-Ic42/IMG_0883.jpg)

Free advice is worth exactly what you payed for it.

Greg

|

![[Image: P1060337_zps162270a3.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060337_zps162270a3.jpg)

![[Image: P1060346_zps83c77575.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060346_zps83c77575.jpg)

![[Image: P1060314_zpsbmcdxl7g.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060314_zpsbmcdxl7g.jpg)

![[Image: P1060371_zpsqrokv7zh.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060371_zpsqrokv7zh.jpg)

![[Image: P1060350_zps16d5d4c7.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/Instrument%20Makers%20Vice/P1060350_zps16d5d4c7.jpg)

![[Image: PB220159_zpsmnrnzvg6.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB220159_zpsmnrnzvg6.jpg)

![[Image: PB220158_zpst9lws133.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB220158_zpst9lws133.jpg)

![[Image: PB010126_zps4mjavtgt.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB010126_zps4mjavtgt.jpg)

![[Image: PA300137_zpsgr9yuzps.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PA300137_zpsgr9yuzps.jpg)

![[Image: PC070184_zpsni6s8s1m.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC070184_zpsni6s8s1m.jpg)

![[Image: PB060143_zpsnraur33b.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB060143_zpsnraur33b.jpg)

![[Image: PB060145_zpsmkdbaniy.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB060145_zpsmkdbaniy.jpg)

![[Image: PB070144_zps9u5wugwg.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB070144_zps9u5wugwg.jpg)

![[Image: PB280170_zps3havbcbd.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB280170_zps3havbcbd.jpg)

![[Image: PB280172_zpsewy8g8fi.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PB280172_zpsewy8g8fi.jpg)

![[Image: PC060172_zpsv8tc3rum.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC060172_zpsv8tc3rum.jpg)

![[Image: PC060174_zps2djgmlg8.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC060174_zps2djgmlg8.jpg)

![[Image: PC060175_zps5fmouua6.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/PC060175_zps5fmouua6.jpg)

![[Image: P10105681_zpsh7hiji4l.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/P10105681_zpsh7hiji4l.jpg)

![[Image: P1060515_zps2gccgwly.jpg]](http://i1066.photobucket.com/albums/u410/RobWilson100/TTA/P1060515_zps2gccgwly.jpg)

![[Image: IMG_1107.jpg]](https://lh3.googleusercontent.com/-DNzOrZQnRaI/UzS66J9-SvI/AAAAAAAACA4/Odr7WfzaCOI/s1280-Ic42/IMG_1107.jpg)

![[Image: IMGP1183.jpg]](https://lh3.googleusercontent.com/-c1B5NjQV2kw/S6EYuET0XRI/AAAAAAAAAGc/k65JNQAqmtA/s1024-Ic42/IMGP1183.jpg)

![[Image: IMGP1252.jpg]](https://lh3.googleusercontent.com/-YMUxXTemdV8/S7vu0FDhg2I/AAAAAAAAAHM/iINZQ4bwAAU/s1440-Ic42/IMGP1252.jpg)

![[Image: IMG_0883.jpg]](https://lh3.googleusercontent.com/-_YPlrR6j280/Upf1-pRGALI/AAAAAAAABr4/scsgGN4RPuM/s1280-Ic42/IMG_0883.jpg)