Posts: 214

Threads: 19

Joined: Oct 2014

Location: SOUTH AFRICA,KZN,DURBAN

09-06-2015, 12:37 AM

(This post was last modified: 09-06-2015, 12:38 AM by aRM.)

]]

Hello there Guys

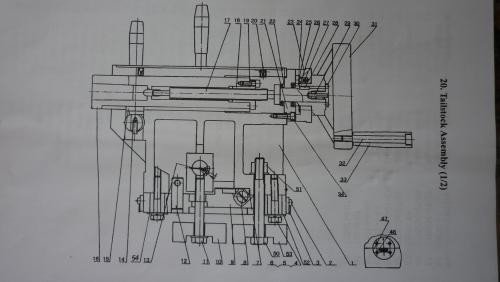

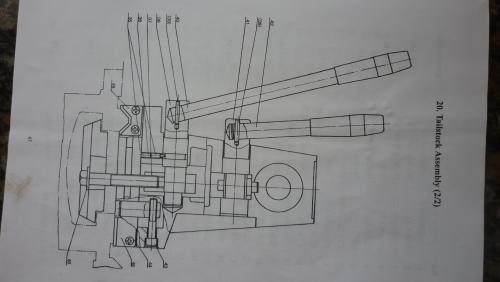

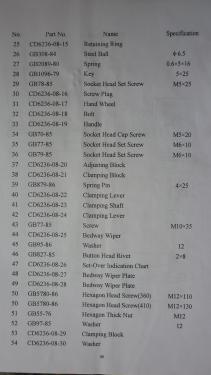

Been having some trouble with our FEEDSCREW Part # 17( tailstock spindle / Barrel ? ) CLAMPING LEVER, PART # 42 which is completely stuck and won't lock onto the Feedscrew ???

Need to rectify this but can't find the necessary Bolts etc to dismantle.

This is a Taiwanese Metre bed machine. Given us good service thus far.TTLA.

Would sincerely appreciate any guidance from the knowledgeable and experienced Gents here

Pics loaded from the manual.

TIA

aRM

Posts: 214

Threads: 19

Joined: Oct 2014

Location: SOUTH AFRICA,KZN,DURBAN

Guys

Son, the custom Knifemaker, helped - sourced the issue, rectified it, refitted and Bob's Your Uncle - better than before !!!

Thanks all the same

aRM

Posts: 168

Threads: 6

Joined: Mar 2012

Location: Surrey, England

Hi aRM,

I think the tailstock quill *should* be locked by the lever 42 rotating the cross-shaft 41 which has an eccentric, forcing the key 15 to bottom in in the groove in the tailstock quill.

The groove in the quill *should* be open-ended at the rear of the barrel, so wind the handle until the feedscrew 17/18 disengages, then the quill will pull forward out of the tailstock body.

Then, examine the key 15 for wear or breakage, see whether the handle will now rotate the cross-shaft - it should do so, raising and lowering key 15.

If it still won't rotate, loosen and if necessary remove the grubscrew 14 - this is accessed from beneath the nose of the tailstock body, directly underneath the cross-shaft. It looks to be in a recess that is half-shown in the last of your pics, at the far left of the pic. This shouldn't really be necessary, although it's possible that the quill has had enough torque applied to shift the cross-shaft and bind up the grubscrew in its slot...

I've seen sheared keys in tailstocks where an excessive cutting load was applied (e.g. a blunt 2" Morse taper drill in very tough materials hanging up and grabbing in an existing bore), this usually jams the tailstock solid, as the remains of the key is rotated out of the slot in the quill... Was the Apprentice doing anything daft before it failed?

A sheared key that hasn't "travelled" will often leave the missing part elsewhere in the slot, so the remains can't contact the quill and lock it - if yours still moves via the handwheel this may be what's happened, luckily the key is just a piece of ordinary keystock!

I hope this makes sense, and helps!

Dave H. (the other one)

Rules are for the obedience of fools, and the guidance of wise men...

(Douglas Bader)

Posts: 214

Threads: 19

Joined: Oct 2014

Location: SOUTH AFRICA,KZN,DURBAN

(09-06-2015, 06:19 AM)Hopefuldave Wrote: Hi aRM,

I think the tailstock quill *should* be locked by the lever 42 rotating the cross-shaft 41 which has an eccentric, forcing the key 15 to bottom in in the groove in the tailstock quill.

The groove in the quill *should* be open-ended at the rear of the barrel, so wind the handle until the feedscrew 17/18 disengages, then the quill will pull forward out of the tailstock body.

Then, examine the key 15 for wear or breakage, see whether the handle will now rotate the cross-shaft - it should do so, raising and lowering key 15.

If it still won't rotate, loosen and if necessary remove the grubscrew 14 - this is accessed from beneath the nose of the tailstock body, directly underneath the cross-shaft. It looks to be in a recess that is half-shown in the last of your pics, at the far left of the pic. This shouldn't really be necessary, although it's possible that the quill has had enough torque applied to shift the cross-shaft and bind up the grubscrew in its slot...

I've seen sheared keys in tailstocks where an excessive cutting load was applied (e.g. a blunt 2" Morse taper drill in very tough materials hanging up and grabbing in an existing bore), this usually jams the tailstock solid, as the remains of the key is rotated out of the slot in the quill... Was the Apprentice doing anything daft before it failed?

A sheared key that hasn't "travelled" will often leave the missing part elsewhere in the slot, so the remains can't contact the quill and lock it - if yours still moves via the handwheel this may be what's happened, luckily the key is just a piece of ordinary keystock!

I hope this makes sense, and helps!

Dave H. (the other one)

Squire DAVE H - the other one ( and only !!! )

Sir, U are a Master

Experienced. Intuitive and right on the money, every time !!! Your treatise made perfect sense. It's patently obvious - "U know Your onions" !!! No piss-Willy BS from U, Sir.

It turned out exactly as U predicted - the GRUB SCREW was squashed alright with the Spring below the Key, missing, but the Key luckily intact.

Just abouts managed to remove the Grubscrew. Replaced both and with no Appy around but ourselves, will just have to be lots more careful working with the Tailstock.

Much appreciate the detailed response.

We now know where to take our troubles in future, if U may

LORD BLESS

aRM

Posts: 168

Threads: 6

Joined: Mar 2012

Location: Surrey, England

The following 2 users Like Hopefuldave's post:

Mayhem (09-07-2015), PixMan (09-07-2015)

Thanks aRM, you're welcome, I try to help! I did a long, miserable and painful spell in Hell, working for an importer of definitely down-to-a-price Chinese lathes and mills, I think I've seen everything that can go wrong, from over-reaching the machine's abilities to the machine basically having very little ability! After a while you notice the same faults cropping up again and again and even my deflicted brain puts 2 and 2 together, files it away for future reference...

Dave H. (the other one)

Rules are for the obedience of fools, and the guidance of wise men...

(Douglas Bader)

Posts: 214

Threads: 19

Joined: Oct 2014

Location: SOUTH AFRICA,KZN,DURBAN

(09-07-2015, 01:54 AM)Hopefuldave Wrote: Thanks aRM, you're welcome, I try to help! I did a long, miserable and painful spell in Hell, working for an importer of definitely down-to-a-price Chinese lathes and mills, I think I've seen everything that can go wrong, from over-reaching the machine's abilities to the machine basically having very little ability! After a while you notice the same faults cropping up again and again and even my deflicted brain puts 2 and 2 together, files it away for future reference...

Dave H. (the other one)

Hello DAVE ( the other one )

Seeing U are right Person, been meaning to ask U a question to avoid a recurrence.

How much of Pressure from the Clamp Lever may we exert on the Quill via the Keyway, say whilst doing heavy Drilling ???

We have used our (newly acquired) MT4 Drills on our machine some time ago. Yes, we understand one may not apply so much force to basically not be able to move the Quill at all, but is there any way we might totally abrade the Key away ???

Regret, seems like a stupid question to bother U, but U know these machines better than anybody else.

TIA

aRM

Posts: 168

Threads: 6

Joined: Mar 2012

Location: Surrey, England

The following 1 user Likes Hopefuldave's post:

aRM (09-07-2015)

09-07-2015, 06:46 PM

(This post was last modified: 09-07-2015, 06:54 PM by Hopefuldave.)

Hi aRM, I don't know these machines specifically, just machines in general ;)

It's unlikely the key would wear, the failure is usually the key shearing or something else shifting and letting it move from its correct position, so...

How much torque the key can take depends on its length and cross-section, and something that occurs to me is that it appears it's only supported by the cross-shaft, hence excess torque will try to force the key and shaft sideways as the quill tries to rotate with the torque applied to the tailstock quill - this would force the cross-shaft out through its bore, bending the grubscrew in its groove and locking it up as you found. Or it could shear leaving you with half(ish) in the quill's groove, the rest in the cross-shaft's groove - this would probably lock the quill up solid and probably badly score either the quill, the tailstock bore, or both :(

The key seems to be all that's preventing the quill rotating, so my instinct says a longer key and a groove cut in the tailstock casting to match the groove in the quill would add a lot of strength to what may be a weak point?

This is just a wild-arsed guess, you understand, but if I were to try that I'd make up a cutter from a piece of HSS the right width to match the slot in the quill and the key, clamp the tailstock down and run the tool back and forth with the carriage, tool held in the toolpost.

If you have a QCTP lowering the tool would be fairly easy, unclamp the holder, rotate the height adjuster a touch, re-clamp taking a few thou" of cut each pass - if you don't have a QCTP you could lay thin (0.002" - 0.003"?) shimstock under the tool, plenty of layers, take a few passes, remove a shim, repeat until deep enough or you die of boredom...

If you should got that route, be sure to clean up and deburr your new slot very thoroughly! Being cast-iron the tailstock casting should cut fairly cleanly, but to be sure...

Hope this helps, rather than confuses!

Dave H. (the other one)

EDIT: Just a thought, if there's enough wall thickness to the tailstock housing, the new key could be positioned at 90 degrees from the original, with a new keyway in the quill - just as strong, maybe easier to cut in the housing as you could adjust the tool into the slot for depth of cut with the cross-slide, but you'd have to also cut a new keyway slot in the quill - if you have access to a mill this wouldn't be such a problem though?

Rules are for the obedience of fools, and the guidance of wise men...

(Douglas Bader)

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

I've seen people use a dog on the drill to prevent it from spinning.

Hunting American dentists since 2015.

Posts: 214

Threads: 19

Joined: Oct 2014

Location: SOUTH AFRICA,KZN,DURBAN

09-08-2015, 12:36 AM

(This post was last modified: 09-08-2015, 12:38 AM by aRM.

Edit Reason: CORRECTION

)

Dave H ( the other one )

Many appreciative thanks again for this most detailed and informative response. U have presented it descriptively so well that even non-machinists like ourselves could grasp Your mindset and reasonably understand the intricacies involved.

We see where U coming from 'cos although the Keyway in the Quill is fairly wide, I'd say approx 10mm, if we recall correctly, the Key itself is mounted, or rather machined on a +- 30mm Diameter Circular Disc and is only about 25-30mm Long. So what U say is absolutely correct in the negligent amount of force being applied to the Quill under Torque. We totally agree, no doubt a very poor weak design.

Now to enforce and proceed with the correction - that's going to be a little tricky for us, at this point in time. We've already re-assembled the Quill with another, albeit weak Spring, (used to keep the Clamp Lever from 'flopping' back), below the Key, and are a little busy currently processing some immediate (Knife) Orders awaiting Delivery - live centre in Tailstock is used to support some Tang Threading under way.

Allow us to use the machine as is for now and let's see how she goes. U've already given us two options for the permanent solution and for us, methinks the former would be a viable option as cutting another Keyway, (directly below the Quill's) in the Casting, would be much easier. It will also give us a chance in the interim, to carefully control, if not monitor our work procedures on the Tailstock and at the same time assess if there's any untoward behaviour from the unit. We will definitely keep U posted should something go amiss.

Once again, THANK U and

LORD BLESS

aRM

|