Just thought I would show how I sometimes cut a thread with a single point tool on a lathe.

32mm diameter x 1.5mm pitch thread.

All the gears have been chosen to give the required pitch of 1.5mm

First I cut a run out .055 deep by about 3mm wide, the depth of cut thread is about .052 deep. Not forgetting the taper at the front.

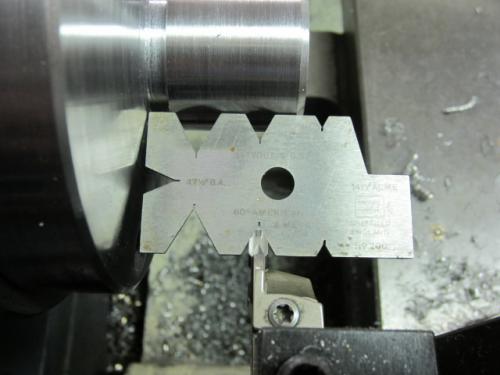

Next I use that little gauge to make sure and align the cutting tool so that it is perpendicular to the work piece.

In this particular method I am not using the compound slide. The depth of cut is applied using the cross slide.

Sometimes I am asked why dont I set the compound slide over at 30deg. I tend to use carbide insert tips these are sharpened on both edges I have paid for that so I am going to use both edges.

Move the cross slide so that the point of the tool just or near as damn it touches the work piece. Zero the cross slide dial.

Now move the tool to the start position, engage the half nuts, these will remain engaged throughout the cutting process.

Next I dialled in a .004 cut. Started the cut. At the end of the cut wind out the cutter so that the apron can be traversed back to the start without the cutter touching the work piece. Dial in the last reading in this case .004. You are now ready to make another pass.

However before the next pass it is best to check the pitch is correct, if there is something wrong, it is still possible at this stage to correct it

Every thing OK dial in .006 do another cut (pass)

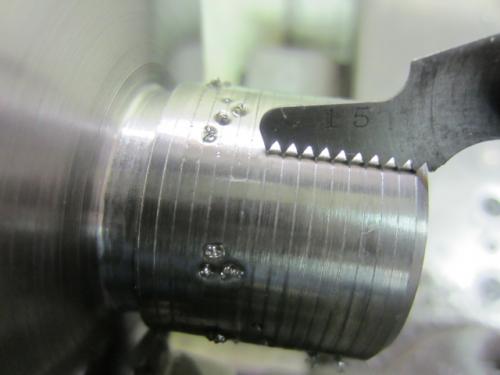

This is nearly half way thru (.022) the depth of cuts where .004 (the first one) then .006 .006 .006 now I am reducing the depth of cut to .004

Also every .008 I just run the tool thru as of the last pass (no increase in depth of cut) to clean the thread up a little.

Now it is just a case of keep going until the nut goes on. Also keep an eye on the total depth of cut .052 Just remember you want it to screw on not a push fit

Towards the end I tend to make very small cuts .001 or less gives a better finish.

Just prior to testing the fit I just made pass on the previous depth of cut, it is possible to see it on the tool tip.

Thats it finished.

Clean it up with a small softish wire brush lightly.

If you have never cut a thread on your lathe well it is not so difficult as you think, you just have to take that first step. This may help you take that first step

DaveH

32mm diameter x 1.5mm pitch thread.

All the gears have been chosen to give the required pitch of 1.5mm

First I cut a run out .055 deep by about 3mm wide, the depth of cut thread is about .052 deep. Not forgetting the taper at the front.

Next I use that little gauge to make sure and align the cutting tool so that it is perpendicular to the work piece.

In this particular method I am not using the compound slide. The depth of cut is applied using the cross slide.

Sometimes I am asked why dont I set the compound slide over at 30deg. I tend to use carbide insert tips these are sharpened on both edges I have paid for that so I am going to use both edges.

Move the cross slide so that the point of the tool just or near as damn it touches the work piece. Zero the cross slide dial.

Now move the tool to the start position, engage the half nuts, these will remain engaged throughout the cutting process.

Next I dialled in a .004 cut. Started the cut. At the end of the cut wind out the cutter so that the apron can be traversed back to the start without the cutter touching the work piece. Dial in the last reading in this case .004. You are now ready to make another pass.

However before the next pass it is best to check the pitch is correct, if there is something wrong, it is still possible at this stage to correct it

Every thing OK dial in .006 do another cut (pass)

This is nearly half way thru (.022) the depth of cuts where .004 (the first one) then .006 .006 .006 now I am reducing the depth of cut to .004

Also every .008 I just run the tool thru as of the last pass (no increase in depth of cut) to clean the thread up a little.

Now it is just a case of keep going until the nut goes on. Also keep an eye on the total depth of cut .052 Just remember you want it to screw on not a push fit

Towards the end I tend to make very small cuts .001 or less gives a better finish.

Just prior to testing the fit I just made pass on the previous depth of cut, it is possible to see it on the tool tip.

Thats it finished.

Clean it up with a small softish wire brush lightly.

If you have never cut a thread on your lathe well it is not so difficult as you think, you just have to take that first step. This may help you take that first step

DaveH