07-31-2017, 03:56 PM

Thinking about a gear cutting question that arose some time ago, I decided to develop some Excel spreadsheets to assist setting up the dividing head on my rotary table. These sheets determine the hole plate increments and number of turns for a required number of spacings and an existing hole plate. Perhaps some of you may be interested in tinkering/customizing the spreadsheets for your own use.

Please note that dividing head setup knowledge is presumed; the procedure is not discussed in this post. The device I have in mind is a typical combination rotary table/dividing head. Also please note that this is one of those processes that are very difficult to explain and very simple to do -

The spreadsheets can determine solutions for required division spacings based on the worm gear ratio and available hole plates of a specific dividing head. Information like this is available from numerous sources like “Machinery’s Handbook” and can be determined with a pocket calculator, with patience, LOL. That procedure is described in one of the spreadsheet margins so I won't repeat it.

I have added a feature that, so far as I know, is unique and isn't available in rotary table/dividing head literature and we'll get to that shortly. This was the main reason for developing the spreadsheet, incidentally. Although the purpose might seem obscure, I have found it to be useful and you may also.

The spreadsheets can be found here:

https://www.dropbox.com/s/jxq6ggqw61dqud...d.xls?dl=0

For some reason, a large error message is displayed when linking. Ignore it and click on the “download” icon at the top right of the page. I think this dropbox deletes files if none have been downloaded in thirty days. If that occurs, contact me and I will upload the spreadsheets again.

First thing to do after downloading the file is to rename and save a copy in case information is accidentally over-written when customizing the spreadsheets to suit individual need.

I have not protected the worksheets because they should be altered by users to suit their own worm gear ratios and available hole plates. Instructions for modifying these are included on the spreadsheets.

After the sheets have been customized by modifying the characteristics of your rotary table/divider head, enter a trial division for which the result is known on the second sheet, the one that addresses exact spacing.

Follow the sample directions on the spreadsheet by first entering the number of crank turns and then examine the table.

Any combination of holes and plates that will produce an exact integer division ratio for the number of turns will be shown. Usually there are multiple correct solutions - pick one that seems convenient.

(If no solution appears, you might try different numbers of turns.)

Sheet 2 can be used to create a division chart for your individual rotary table/dividing head with your hole plates. By entering integer turns, starting with "0" and increasing to some practical value, all division ratios will be shown for all of the hole plates and sector options.

It is possible that NO exact solution exists for the hole plate numbers that have been entered and the desired spacing. That is exactly the situation that prompted me to create these spreadsheets. It seemed to me that an approximate solution, within the tolerance of the requirement, might save one the time required to make a new, custom hole plate or the money to buy one.

If you determine that there is no exact solution, then the first or third sheets might be useful. The first sheet can identify a hole plate and number of hole increments that are within a tolerance that you specify but are not exact spacings.

The most troublesome spacings are those that equal prime numbers, which are divisible only by themselves or by one. If the prime number is not on one of your number plates, then you are limited to this approximation method or using the rotary table rather than dividing head (or making a new hole plate).

In the sample problem shown on the first spreadsheet, it is assumed that a division ratio of 17 is required and cannot be achieved with the available hole plates - the ones that are shown in the example. (Note that although the sheet is titled “Approximate Division” it will also find exact solutions if they exist.)

For the situation described above, maybe a small error is permissible - perhaps because you are making the mating part or because common sense indicates it or because the drawing tolerance allows it.

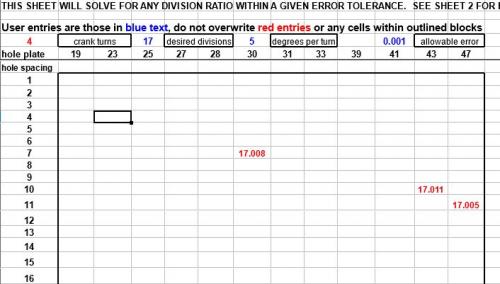

This is a portion of the first spread sheet:

It should probably be noted that if the part doesn't fit - EVEN if it is within drawing tolerance - the guy who made the part isn't going to be a hero, doesn't make any difference where the fault lies. The person who made the drawing usually doesn’t pay a lot of attention to angular tolerances because he/she thinks that they are understood or doesn’t know that it’s important.

So it may be wise to check angular tolerances with the design engineer before making a manufacturing decision that might impact the project. A "heads-up" call like this, with an intelligent question, might make a design engineer remember you and that can be helpful when soliciting new business !

Continuing the example provided on the spread sheet, rather than dividing a circle into 17 exact, even spaces, maybe a division within a tolerance of 1% is acceptable (which could result in an error of 0.17 spaces).

(Don’t enter a number of turns for the approximate spacing method on sheet 1, by the way, it will be calculated and entered automatically.)

Instead of a "perfect" angle of 21.176 degrees between 17 holes, the angle would be 20.967 degrees - an error of 12.68 minutes. If you enter an allowable error of 1% (numerical value of .01) in the appropriate cell of sheet 1, multiple solutions are shown, all of them close to (but not exactly) 17.

BUT the error on some of these solutions will be cumulative: an error of 1% applied to 17 spaces will result in an overall error of 17% so be careful about the allowable error you specify. If you REALLY need a 1% error over the full 360 degrees then you need to specify an allowable error of 1% divided by the number of divisions.

In this example exercise, the tolerance you might want to specify would be 1% divided by the number of hole spacings: .01 / 17 = .00059 or about a .06 %. error – pretty good !

Generally one is seeking the best approximation for a specific division ratio and reducing the allowable error takes only a few seconds with the spread sheet if a solution exists.

For the example hole plates provided on the spread sheet, reducing the error from 1% to 0.1% immediately narrows the prospective division ratios from a dozen or so to three choices. The division ratio of 17.005 is clearly the best (11 hole incremental spacing on a 47 hole plate, 4 turns). The cumulative error over a complete circle is only 6 arc-minutes which is accurate enough for most applications that the HSM encounters, including gears.

THIS procedure for approximation was the main reason for producing the spread sheet. It's not really hard to work out exact solutions for existing hole plates when the dividing head has the right hole plate and worm gear.

When no exact solution can be found with the existing dividing head, you can resort to the rotary table alone and deal with the fractional angles and calculations required and keeping track of them. This is no fun but you’re stuck with it in some cases !

So, if a little error is acceptable, the use of an existing hole plate can work fine, rather than spending hours to machine a custom hole plate that might never be used again. But there is no assurance that a combination of hole increments/turns/plates will provide the required spacing within the desired tolerance.

There is another method that could work if the above fails but I have not prepared a spread sheet for it and it is sort of complicated to explain. The rare need probably doesn’t justify the time required to make the spread sheet.

Diverting back to using the rotary table function to achieve the desired spacing (within the degree of accuracy that the rotary table can provide). The third sheet may make this simple procedure easier.

A common problem with using a rotary table for increments that aren't easily remembered (10 degrees, 30 degrees, 90 degrees and so forth) is keeping track of degrees, minutes and seconds - or the decimal equivalents - as the table is rotated. Think about that for the previous example of 17 spaces.

The first setting, if the table is adjusted to start at 0 degrees, is at 21 degrees 10.6 minutes (or 21 deg 10 min 35 sec), next spacing is 42 degrees 21 minutes (or 42 deg 21 min 11 sec) , third setting is 63 degrees 32 minutes and so forth. You can see the problem – one would have to calculate and write down all of these settings before starting or keep incrementing your calculator and referring to it.

If you work in degrees, minutes and seconds and are doing it manually, you will probably give up quickly - the chance of math errors, forgetting or entering incorrectly is quite possible while a dividing head usually does not have his problem when sector arms are set and used properly.

Working in decimal degrees is simple BUT the rotary table must then be graduated in decimal degrees or we're right back to the degrees, minutes, seconds problem.

The spreadsheet calculates and accumulates these angular divisions - when you've indexed to the next location and find that you are back to "0" then you are done - assuming that full circle divisions are required. (This spreadsheet just keeps track of the angles as you index so that you don't have to make a checklist.)

The most useful purpose of the third sheet is to make new, custom hole plates. It is practical to do this because any error introduced (i.e. rounding off the angles) will typically be divided by the worm gear ratio.

For example, if an inexpensive rotary table has the capability of indexing to one-third of a degree (as interpolated by anyone with good vision) and has a worm gear ratio of 92, then one can make a hole plate that has an accuracy of around 13 arc-seconds. This assumes that the rotary table graduations and gears have no errors.

Ignoring the error of the worm and gear in the rotary table, then the new hole plate can be used to produce angles whose tolerance will again be reduced by the worm gear ratio. A point of diminishing returns is reached because the worm and gear DO have finite errors as do the hand-wheel graduations.

One generation of error reduction is probably practical for the imported equipment owned by the average HSM. Even so, it is completely possible that hole plates made in this simple manner will be superior to those supplied with inexpensive dividing heads.

Since rotary tables have various types of graduations, sheet 3 is one that you'll also want to customize. I've arbitrarily configured that sheet in degrees, minutes and seconds and decimal fractions. My old rotary table is oddly configured - it displays full degrees, increments of 2 minutes and a 10:1 vernier, every division of which is 12 seconds. My personal spread sheet has been altered to suit this weird graduation scheme but obviously I didn't want to inflict my situation on others, it is a total PITA !

This procedure may seem overly complicated and it is until practice smooths the process. In fact it will probably never be used by most of us but when that one requirement is encountered … a special gear with a non-standard number of teeth for example.

Since I didn't intend anyone else to use them, the spreadsheets are not very user-friendly; you'll need to work with them for a while, using examples with known results.

One might tape a piece of paper to the table and make a pencil mark (from the same location each time) to see if the required spacings are achieved when you determine the number of turns and number of holes to be skipped on the hole plate. I’ve not tried this but it seems that it would be a decent practice tool.

This is my own inexpensive rotary table and beside it are the hole plate with sector arms and the crank with locating/locking pin for conversion to a dividing head. In usage, all of the components to the left of the detent with the black knob are removed and replaced by the dividing head components. The process takes less than two minutes.

A toolmaker’s vise is mounted to the table in this photo; 3-jaw and 4-jaw chucks are commonly mounted to the table as well. Note that the table is bolted to a scrap of plywood to which are attached four casters.

Since the table is heavy, I find it convenient to roll it around from it’s storage position on the workbench, to a location close to a milling machine then unbolt the table from the little “cart” and lift it the short distance to one of the mill tables.

NOTE: Successful usage and accuracy are not implied from the spread sheets and the described process although the procedures are expected to be useful and accurate within the limits specified in the text. But you use these at your own risk, OK ? (Oh yeah, "customer support" is also not implied although I might be able to answer limited questions.)

Cheers,

randyc

Please note that dividing head setup knowledge is presumed; the procedure is not discussed in this post. The device I have in mind is a typical combination rotary table/dividing head. Also please note that this is one of those processes that are very difficult to explain and very simple to do -

The spreadsheets can determine solutions for required division spacings based on the worm gear ratio and available hole plates of a specific dividing head. Information like this is available from numerous sources like “Machinery’s Handbook” and can be determined with a pocket calculator, with patience, LOL. That procedure is described in one of the spreadsheet margins so I won't repeat it.

I have added a feature that, so far as I know, is unique and isn't available in rotary table/dividing head literature and we'll get to that shortly. This was the main reason for developing the spreadsheet, incidentally. Although the purpose might seem obscure, I have found it to be useful and you may also.

The spreadsheets can be found here:

https://www.dropbox.com/s/jxq6ggqw61dqud...d.xls?dl=0

For some reason, a large error message is displayed when linking. Ignore it and click on the “download” icon at the top right of the page. I think this dropbox deletes files if none have been downloaded in thirty days. If that occurs, contact me and I will upload the spreadsheets again.

First thing to do after downloading the file is to rename and save a copy in case information is accidentally over-written when customizing the spreadsheets to suit individual need.

I have not protected the worksheets because they should be altered by users to suit their own worm gear ratios and available hole plates. Instructions for modifying these are included on the spreadsheets.

After the sheets have been customized by modifying the characteristics of your rotary table/divider head, enter a trial division for which the result is known on the second sheet, the one that addresses exact spacing.

Follow the sample directions on the spreadsheet by first entering the number of crank turns and then examine the table.

Any combination of holes and plates that will produce an exact integer division ratio for the number of turns will be shown. Usually there are multiple correct solutions - pick one that seems convenient.

(If no solution appears, you might try different numbers of turns.)

Sheet 2 can be used to create a division chart for your individual rotary table/dividing head with your hole plates. By entering integer turns, starting with "0" and increasing to some practical value, all division ratios will be shown for all of the hole plates and sector options.

It is possible that NO exact solution exists for the hole plate numbers that have been entered and the desired spacing. That is exactly the situation that prompted me to create these spreadsheets. It seemed to me that an approximate solution, within the tolerance of the requirement, might save one the time required to make a new, custom hole plate or the money to buy one.

If you determine that there is no exact solution, then the first or third sheets might be useful. The first sheet can identify a hole plate and number of hole increments that are within a tolerance that you specify but are not exact spacings.

The most troublesome spacings are those that equal prime numbers, which are divisible only by themselves or by one. If the prime number is not on one of your number plates, then you are limited to this approximation method or using the rotary table rather than dividing head (or making a new hole plate).

In the sample problem shown on the first spreadsheet, it is assumed that a division ratio of 17 is required and cannot be achieved with the available hole plates - the ones that are shown in the example. (Note that although the sheet is titled “Approximate Division” it will also find exact solutions if they exist.)

For the situation described above, maybe a small error is permissible - perhaps because you are making the mating part or because common sense indicates it or because the drawing tolerance allows it.

This is a portion of the first spread sheet:

It should probably be noted that if the part doesn't fit - EVEN if it is within drawing tolerance - the guy who made the part isn't going to be a hero, doesn't make any difference where the fault lies. The person who made the drawing usually doesn’t pay a lot of attention to angular tolerances because he/she thinks that they are understood or doesn’t know that it’s important.

So it may be wise to check angular tolerances with the design engineer before making a manufacturing decision that might impact the project. A "heads-up" call like this, with an intelligent question, might make a design engineer remember you and that can be helpful when soliciting new business !

Continuing the example provided on the spread sheet, rather than dividing a circle into 17 exact, even spaces, maybe a division within a tolerance of 1% is acceptable (which could result in an error of 0.17 spaces).

(Don’t enter a number of turns for the approximate spacing method on sheet 1, by the way, it will be calculated and entered automatically.)

Instead of a "perfect" angle of 21.176 degrees between 17 holes, the angle would be 20.967 degrees - an error of 12.68 minutes. If you enter an allowable error of 1% (numerical value of .01) in the appropriate cell of sheet 1, multiple solutions are shown, all of them close to (but not exactly) 17.

BUT the error on some of these solutions will be cumulative: an error of 1% applied to 17 spaces will result in an overall error of 17% so be careful about the allowable error you specify. If you REALLY need a 1% error over the full 360 degrees then you need to specify an allowable error of 1% divided by the number of divisions.

In this example exercise, the tolerance you might want to specify would be 1% divided by the number of hole spacings: .01 / 17 = .00059 or about a .06 %. error – pretty good !

Generally one is seeking the best approximation for a specific division ratio and reducing the allowable error takes only a few seconds with the spread sheet if a solution exists.

For the example hole plates provided on the spread sheet, reducing the error from 1% to 0.1% immediately narrows the prospective division ratios from a dozen or so to three choices. The division ratio of 17.005 is clearly the best (11 hole incremental spacing on a 47 hole plate, 4 turns). The cumulative error over a complete circle is only 6 arc-minutes which is accurate enough for most applications that the HSM encounters, including gears.

THIS procedure for approximation was the main reason for producing the spread sheet. It's not really hard to work out exact solutions for existing hole plates when the dividing head has the right hole plate and worm gear.

When no exact solution can be found with the existing dividing head, you can resort to the rotary table alone and deal with the fractional angles and calculations required and keeping track of them. This is no fun but you’re stuck with it in some cases !

So, if a little error is acceptable, the use of an existing hole plate can work fine, rather than spending hours to machine a custom hole plate that might never be used again. But there is no assurance that a combination of hole increments/turns/plates will provide the required spacing within the desired tolerance.

There is another method that could work if the above fails but I have not prepared a spread sheet for it and it is sort of complicated to explain. The rare need probably doesn’t justify the time required to make the spread sheet.

Diverting back to using the rotary table function to achieve the desired spacing (within the degree of accuracy that the rotary table can provide). The third sheet may make this simple procedure easier.

A common problem with using a rotary table for increments that aren't easily remembered (10 degrees, 30 degrees, 90 degrees and so forth) is keeping track of degrees, minutes and seconds - or the decimal equivalents - as the table is rotated. Think about that for the previous example of 17 spaces.

The first setting, if the table is adjusted to start at 0 degrees, is at 21 degrees 10.6 minutes (or 21 deg 10 min 35 sec), next spacing is 42 degrees 21 minutes (or 42 deg 21 min 11 sec) , third setting is 63 degrees 32 minutes and so forth. You can see the problem – one would have to calculate and write down all of these settings before starting or keep incrementing your calculator and referring to it.

If you work in degrees, minutes and seconds and are doing it manually, you will probably give up quickly - the chance of math errors, forgetting or entering incorrectly is quite possible while a dividing head usually does not have his problem when sector arms are set and used properly.

Working in decimal degrees is simple BUT the rotary table must then be graduated in decimal degrees or we're right back to the degrees, minutes, seconds problem.

The spreadsheet calculates and accumulates these angular divisions - when you've indexed to the next location and find that you are back to "0" then you are done - assuming that full circle divisions are required. (This spreadsheet just keeps track of the angles as you index so that you don't have to make a checklist.)

The most useful purpose of the third sheet is to make new, custom hole plates. It is practical to do this because any error introduced (i.e. rounding off the angles) will typically be divided by the worm gear ratio.

For example, if an inexpensive rotary table has the capability of indexing to one-third of a degree (as interpolated by anyone with good vision) and has a worm gear ratio of 92, then one can make a hole plate that has an accuracy of around 13 arc-seconds. This assumes that the rotary table graduations and gears have no errors.

Ignoring the error of the worm and gear in the rotary table, then the new hole plate can be used to produce angles whose tolerance will again be reduced by the worm gear ratio. A point of diminishing returns is reached because the worm and gear DO have finite errors as do the hand-wheel graduations.

One generation of error reduction is probably practical for the imported equipment owned by the average HSM. Even so, it is completely possible that hole plates made in this simple manner will be superior to those supplied with inexpensive dividing heads.

Since rotary tables have various types of graduations, sheet 3 is one that you'll also want to customize. I've arbitrarily configured that sheet in degrees, minutes and seconds and decimal fractions. My old rotary table is oddly configured - it displays full degrees, increments of 2 minutes and a 10:1 vernier, every division of which is 12 seconds. My personal spread sheet has been altered to suit this weird graduation scheme but obviously I didn't want to inflict my situation on others, it is a total PITA !

This procedure may seem overly complicated and it is until practice smooths the process. In fact it will probably never be used by most of us but when that one requirement is encountered … a special gear with a non-standard number of teeth for example.

Since I didn't intend anyone else to use them, the spreadsheets are not very user-friendly; you'll need to work with them for a while, using examples with known results.

One might tape a piece of paper to the table and make a pencil mark (from the same location each time) to see if the required spacings are achieved when you determine the number of turns and number of holes to be skipped on the hole plate. I’ve not tried this but it seems that it would be a decent practice tool.

This is my own inexpensive rotary table and beside it are the hole plate with sector arms and the crank with locating/locking pin for conversion to a dividing head. In usage, all of the components to the left of the detent with the black knob are removed and replaced by the dividing head components. The process takes less than two minutes.

A toolmaker’s vise is mounted to the table in this photo; 3-jaw and 4-jaw chucks are commonly mounted to the table as well. Note that the table is bolted to a scrap of plywood to which are attached four casters.

Since the table is heavy, I find it convenient to roll it around from it’s storage position on the workbench, to a location close to a milling machine then unbolt the table from the little “cart” and lift it the short distance to one of the mill tables.

NOTE: Successful usage and accuracy are not implied from the spread sheets and the described process although the procedures are expected to be useful and accurate within the limits specified in the text. But you use these at your own risk, OK ? (Oh yeah, "customer support" is also not implied although I might be able to answer limited questions.)

Cheers,

randyc