12-10-2017, 10:14 PM

Hey Guys.

I would like to find out how some of you guys would tackle this project of switching my lathe over to a Quick Change Tool Post. I have been thinking about this for a while now as to what would be the best way to do it. I have an idea in my head. But I would like to see if there is better ways of doing the conversion.

For reference my lathe is a Craftex CX-701. It came with the standard Four Way Tool Post. I purchased a Piston Style Quick Change Tool Post from the same company the lathe was originally purchased from. It said will fit 12" lathe. Which is what my lathe is.

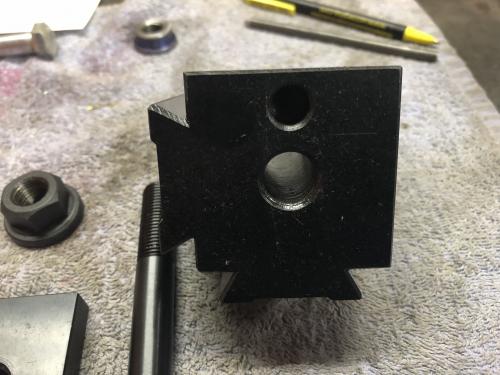

Now my compound doesn't have a T Slot for the tool post. Which is what this QCTP is really designed for. It came with a flat plate to make into a T Nut and slide into the compont slide. Mine has a stud that is pressed in from the bottom of the compound slide and has a small roll pin going threw a flange into the bottom of the compound slide to keep it from rotating. The whole stud will come out from the bottom leaving the flat surface of the compound slide with a 3/4" hole.

What I'm trying to accomplish is to have it so I can switch back and forth from the QCTP & Four Way. I don't know if I will ever really need to switch back to the Four Way for any reason. But I would like to keep that option open if possible.

The stud for the four way is a small dia. and to short to work with the QCTP. Plus the four way has a large boss (3/4") at the base of the stud that fits into the base of the tool post itself.

Where to QCTP has the same bore top to bottom. Around 1/2".

Do you guys have any ideas of how I should do this or if you have had to do it on your lathes, any pictures!!

My idea of how to do this was to make a insert that will press into the bottom of the compound slide. I would use the roll pin idea from the original tool post mount to keep the insert from spinning. The insert will then be threaded to match the threads on the QCTP Stud. Once threaded into the insert I should be able to use the QCTP. Then I was thinking of making a new stud for the Four Way Tool Post that is threaded on the bottom to match the insert as well. If I wanted to switch to the Four Way, it would just be a matter of switching the studs. But I'm open to any suggestion, as long as I have to tooling to pull it off.

Also. My Four Way Tool Post Stud has a weird Cut in it just above the boss at the bottom. I have watch videos where guys show the stud on their Craftex lathes, and I can't see that cut in theirs. But I also have not seen a video with my exact lathe either. Any idea as to why that cut is there?

Thanks

Trevor

I would like to find out how some of you guys would tackle this project of switching my lathe over to a Quick Change Tool Post. I have been thinking about this for a while now as to what would be the best way to do it. I have an idea in my head. But I would like to see if there is better ways of doing the conversion.

For reference my lathe is a Craftex CX-701. It came with the standard Four Way Tool Post. I purchased a Piston Style Quick Change Tool Post from the same company the lathe was originally purchased from. It said will fit 12" lathe. Which is what my lathe is.

Now my compound doesn't have a T Slot for the tool post. Which is what this QCTP is really designed for. It came with a flat plate to make into a T Nut and slide into the compont slide. Mine has a stud that is pressed in from the bottom of the compound slide and has a small roll pin going threw a flange into the bottom of the compound slide to keep it from rotating. The whole stud will come out from the bottom leaving the flat surface of the compound slide with a 3/4" hole.

What I'm trying to accomplish is to have it so I can switch back and forth from the QCTP & Four Way. I don't know if I will ever really need to switch back to the Four Way for any reason. But I would like to keep that option open if possible.

The stud for the four way is a small dia. and to short to work with the QCTP. Plus the four way has a large boss (3/4") at the base of the stud that fits into the base of the tool post itself.

Where to QCTP has the same bore top to bottom. Around 1/2".

Do you guys have any ideas of how I should do this or if you have had to do it on your lathes, any pictures!!

My idea of how to do this was to make a insert that will press into the bottom of the compound slide. I would use the roll pin idea from the original tool post mount to keep the insert from spinning. The insert will then be threaded to match the threads on the QCTP Stud. Once threaded into the insert I should be able to use the QCTP. Then I was thinking of making a new stud for the Four Way Tool Post that is threaded on the bottom to match the insert as well. If I wanted to switch to the Four Way, it would just be a matter of switching the studs. But I'm open to any suggestion, as long as I have to tooling to pull it off.

Also. My Four Way Tool Post Stud has a weird Cut in it just above the boss at the bottom. I have watch videos where guys show the stud on their Craftex lathes, and I can't see that cut in theirs. But I also have not seen a video with my exact lathe either. Any idea as to why that cut is there?

Thanks

Trevor