Posts: 4,367

Threads: 177

Joined: Feb 2012

Location: Missouri, USA

Ed, how is the steel strip attached to the holder? Is it glued on or is the plate laid on the platen and the holder printed around it (inset)? I don't know squat about 3D printing but wondered if it is possible to do that. Set up a row of magnets and print the holder around them for example.

Willie

Posts: 684

Threads: 42

Joined: Mar 2012

Location: Rochester, NY

The following 1 user Likes rleete's post:

EdK (05-03-2021)

Yes, that can be done. You have to watch the print and pause it, then work quickly to put in the insert and resume printing.

Haven't tried it myself, but I have seen videos explaining the process.

Full of ideas, but slow to produce parts

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(05-03-2021, 04:00 AM)Highpower Wrote: how is the steel strip attached to the holder? Is it glued on or is the plate laid on the platen and the holder printed around it (inset)?

It's inset and glued into a groove in the printed part. I originally had it on the opposite side of the with flange about .020" of plastic between it and the magnets but that didn't work out so well so I put it on the top side of the flange instead.

I didn't know about being able to insert something into a print as rleet suggested. I'll have to try that sometime.

Ed

Posts: 2,596

Threads: 99

Joined: Dec 2014

Location: Michigan

The following 1 user Likes Vinny's post:

EdK (05-03-2021)

If you need extra pull, put a couple of magnets under the steel strip.

Posts: 4,367

Threads: 177

Joined: Feb 2012

Location: Missouri, USA

The following 1 user Likes Highpower's post:

EdK (07-18-2022)

I was thinking maybe use a bar magnet instead of the steel plate. Seems like 1/8" x 1/2" bar magnets are pretty common.

That would be pretty cool to be able to print parts with the magnets inside and be able to connect them together like an Apple charging port connector.

Willie

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

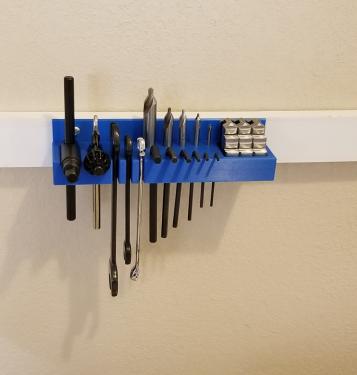

Printed this tool holder for the most used tools for the mini-lathe. I'll hang it on the wall next to the mini-lathe.

Ed

Posts: 4,367

Threads: 177

Joined: Feb 2012

Location: Missouri, USA

The following 1 user Likes Highpower's post:

EdK (06-21-2021)

Hey Ed,

These have been popping up in my Amazon 'suggestions' lately for some reason and I have been ignoring them. I assumed it was for a set of brass drift punches, which I already have. I was looking for something else today and these came up again. Curiosity got the better of me and it turns out I was wrong. After your post above it hit me that these might be a perfect project for your new lathe to go along with your printer.

https://www.amazon.com/Heat-Set-Inserts-...VQLD&psc=1

https://www.amazon.com/Heat-Set-Inserts-...VQLD&psc=1

Willie