10-11-2012, 09:42 AM

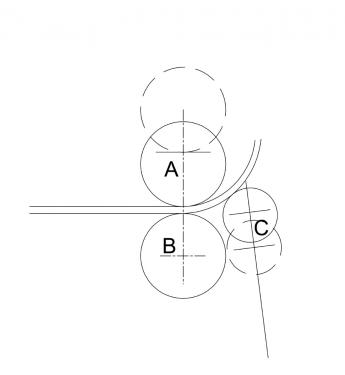

The way it works. This drawing may help.

Roller B is fixed apart from rotating; the crank handle is attached to this roller. Roller A moves up and down to allow the material to be pinched. Roller C moves up and down (at a slight angle) this roller controls the size or diameter of the material being formed,

In my case Roller A & B are 1 diameter and Roller C is 5/8 diameter.

It will roll brass, copper and aluminium up to 1/8 thick, however it is a light duty roller and 1/8 steel may well be too much for it.

DaveH

Roller B is fixed apart from rotating; the crank handle is attached to this roller. Roller A moves up and down to allow the material to be pinched. Roller C moves up and down (at a slight angle) this roller controls the size or diameter of the material being formed,

In my case Roller A & B are 1 diameter and Roller C is 5/8 diameter.

It will roll brass, copper and aluminium up to 1/8 thick, however it is a light duty roller and 1/8 steel may well be too much for it.

DaveH