09-22-2013, 05:45 PM

Some months ago, my favourite tool store had a 6" 4-jaw chuck on sale for $65. I had been thinking about replacing the worn out one on my Hercus (SB9A) lathe, so it seemed like the ideal opportunity.

Turns out that not too many suppliers sell 6 1/4" backplates with 1 1/2" x 8 spindle threads. That's what the diameter of the chuck actually is. I tried to find one on-line, to no avail. Several trips to the scrappers didn't net me an appropriate piece of metal to make one. I even considered casting one from aluminum.

In the meantime, I wired a new shop for one of the owners of the scrap yard - a 3500 square foot addition to his garage. He (Kelly) was quite pleased with the result. During the construction, I went to the yard a few times to browse. On one trip, I noticed some broken pieces of cast iron that could come in handy. Kelly says, "Throw them on your bike." Last trip, I found another piece from the same parent chunk that was about 1 1/2" thick and very large. I was heading for the scale and Kelly says, "Throw it in your van. It's a tip for the good job." The two top pieces (and one thicker one that missed photo day) were from the first trip. The big one was from the last trip.

It takes a bit of cutting to get a 6 1/2" circle out of a piece that's too big for a 9 x 12 bandsaw.

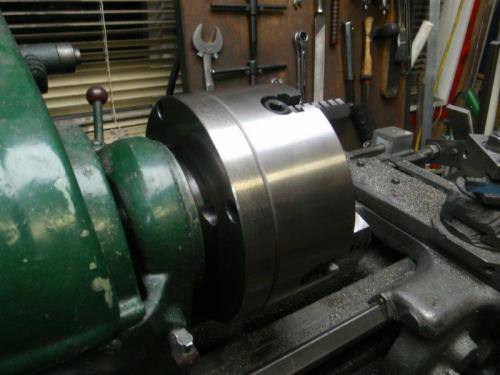

With the blank bolted to the faceplate, the spindle side is faced and bored first.

Then the centre is threaded for the spindle.

After that, the piece is removed from the faceplate and the other side is faced and the register step cut.

Back to the rotary table on the Victoria for drilling and counterboring the bolt holes.

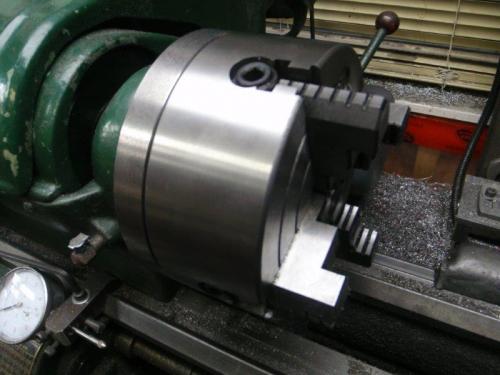

I'm quite pleased with the results. The rim of the backplate shows a TIR of less than 0.0005" and the body of the chuck shows a TIR of 0.002".

Turns out that not too many suppliers sell 6 1/4" backplates with 1 1/2" x 8 spindle threads. That's what the diameter of the chuck actually is. I tried to find one on-line, to no avail. Several trips to the scrappers didn't net me an appropriate piece of metal to make one. I even considered casting one from aluminum.

In the meantime, I wired a new shop for one of the owners of the scrap yard - a 3500 square foot addition to his garage. He (Kelly) was quite pleased with the result. During the construction, I went to the yard a few times to browse. On one trip, I noticed some broken pieces of cast iron that could come in handy. Kelly says, "Throw them on your bike." Last trip, I found another piece from the same parent chunk that was about 1 1/2" thick and very large. I was heading for the scale and Kelly says, "Throw it in your van. It's a tip for the good job." The two top pieces (and one thicker one that missed photo day) were from the first trip. The big one was from the last trip.

It takes a bit of cutting to get a 6 1/2" circle out of a piece that's too big for a 9 x 12 bandsaw.

With the blank bolted to the faceplate, the spindle side is faced and bored first.

Then the centre is threaded for the spindle.

After that, the piece is removed from the faceplate and the other side is faced and the register step cut.

Back to the rotary table on the Victoria for drilling and counterboring the bolt holes.

I'm quite pleased with the results. The rim of the backplate shows a TIR of less than 0.0005" and the body of the chuck shows a TIR of 0.002".

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

, it should serve you for many years to come

, it should serve you for many years to come

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)

I was thinking there would be small stress fractures and would turn terrible. Just another nugget of knowledge!

I was thinking there would be small stress fractures and would turn terrible. Just another nugget of knowledge! :

: