Posts: 139

Threads: 14

Joined: Apr 2012

Location: Nelson, BC, Canada

So I had a gent show up not long ago and asked if I was interested in a Genie Lift. Said it was 800 lbs capacity with 5 foot lift.

Turned out to be a Genie Mix-N-Match in really good shape with only a bit of scuffing of the paint. The parts listing in the tube on the back of the mast was dated April 1982 and the Serial number might further date it to about 1988

Steel plate deck slides forward a bit to help grab loads from back of truck.

I figured I could not refuse the deal

It has come in very handy for saving my back from myself lifting planers and other tools that should not be lifted by oneself.

Walter

starlight_tools, proud to be a member of Metalworking Forum since Apr 2012.

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

Well that's definitely worth a

Nice score!

Ed

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

I'll reserve the  'til we now what you paid for it.

If it was free gratis the  will most certainly follow.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 139

Threads: 14

Joined: Apr 2012

Location: Nelson, BC, Canada

10-16-2013, 11:18 AM

(This post was last modified: 10-16-2013, 03:32 PM by starlight_tools.)

(10-16-2013, 06:38 AM)stevec Wrote: I'll reserve the  'til we now what you paid for it. 'til we now what you paid for it.

If it was free gratis the  will most certainly follow. will most certainly follow.

Let's just say that I really did not want the gent to know just how badly I wanted it.

I convinced a buddy the he needed to make a Timmy's run to Castlager that evening. (Tim Horton's Coffee and Donut Shop and not a very hard arm twist) so we had an excuse to be driving past his house. We got there and had a quick look at it, sort of brushed it off, then went on to repair the grinder that was the "trade" when the grinder was done, commented that "ya that will probably do" loaded up the unit in the Truck and High-tailed it out of there.

Here is the new equivalent units.

https://genie-mf.com/index.cfm/products/...enie-Lifts

My cost parts and labour to repair a few angle grinders.

Yup, I suck!

Walter

starlight_tools, proud to be a member of Metalworking Forum since Apr 2012.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Nice score Walter, so I'm afraid you get one of these  (in a nice way)

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

10-16-2013, 03:11 PM

(This post was last modified: 10-16-2013, 03:12 PM by stevec.)

Walter, thanks for the info (the link brought me to a "sorry, page not found" page).

Anyway, maybe it's a good thing we're a huge country apart, that way I'm not apt to be "ripped off" by Walter the smooth wheeler dealer.

That said, here's your official  from me.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 139

Threads: 14

Joined: Apr 2012

Location: Nelson, BC, Canada

Steve

Link should work now.

https://genie-mf.com/index.cfm/products/...enie-Lifts

And as for ripping off, nope, he said how much, I agreed on the price and followed through with my end of the bargain.

Walter

starlight_tools, proud to be a member of Metalworking Forum since Apr 2012.

Posts: 139

Threads: 14

Joined: Apr 2012

Location: Nelson, BC, Canada

The following 4 users Like starlight_tools's post:

EdK (06-19-2014), PixMan (06-19-2014), Highpower (06-19-2014), DaveH (06-20-2014)

06-19-2014, 07:58 PM

(This post was last modified: 06-19-2014, 08:04 PM by starlight_tools.)

OK so did a few mods to the Genie lift.

Started by adding a set of wheels to the top of the mast, so that when the lift is layed down it will roll around, makes it handy to slide into the back of the truck without scratching the bed of the new F150.

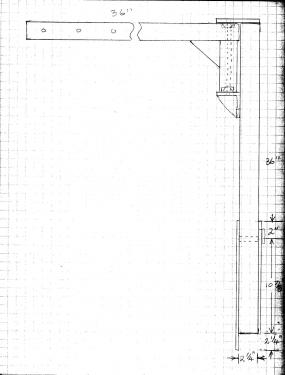

Then modified the back rest from a simple H that bolted onto the raising mechanism to insert a section of 2" Hitch Receiver Tube, so that I can add a jib boom.

The tube bolts on top and bottom and also there is an angle iron that rests over the raising plate and the bolt then sandwiches it together.

Jib Boom is still on drawing board, but at least now the Genie is set up for it.

Then added Eye Bolts to each of the back rests for ratchet straps

Hope these pictures turn out clear as the Canon bit the dust so I had to use the Milwaukee Inspection Camera.

Walter

starlight_tools, proud to be a member of Metalworking Forum since Apr 2012.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

06-19-2014, 08:29 PM

(This post was last modified: 06-19-2014, 08:30 PM by PixMan.)

Nice modifications! All the more useful that way.

Posts: 139

Threads: 14

Joined: Apr 2012

Location: Nelson, BC, Canada

OK so next phase is done.

Added outriggers for side stabilization. They slide into the tube socket of the frame and pin with the same pin that locks in the front Legs. I still have to make longer pins as the current ones do not reach all the way through the legs.

Outrigger in "in" position

Outrigger in "out" position

Outrigger stored

Both outriggers stored back view

Both outriggers stored front view.

Also ordered the bearing assembly for the jib crane attachment.

Walter

starlight_tools, proud to be a member of Metalworking Forum since Apr 2012.

|