Posts: 532

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

12-15-2013, 12:25 AM

(This post was last modified: 12-15-2013, 12:29 AM by Hawkeye.)

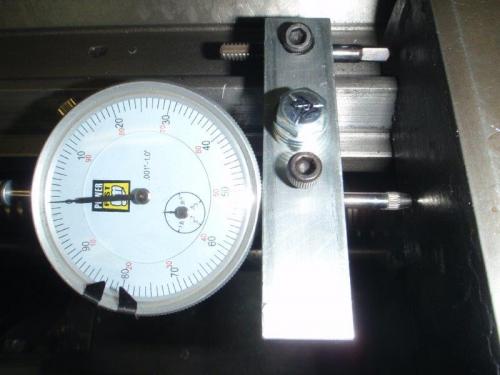

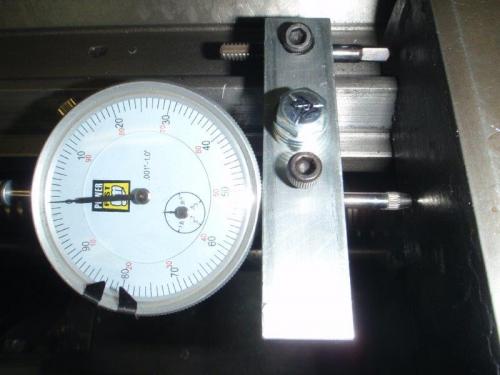

I'm getting to know my 'new' Storebro lathe by making up some accessories that I find useful. A few times, I have been missing the carriage stop that I have on the Hercus lathe. I corrected that deficiency today. This design includes both a hard stop and a dial indicator to give advanced notice that the stop is coming up. With a bit of practice, you can drop out of power feed with about 5 thou left to turn by hand.

I have it adjusted to zero out on the hard stop after 1/2" of contact. I'll replace the hex-head bolt when I can get a 2" SHCS.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Nice job Mike - you may want to get one of the handles that Ed used when he made his carriage stop.

I cannot recall the name of them but I will be using one when I try my second attempt at a carriage lock for my lathe.

Hunting American dentists since 2015.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

The hard stop looks a lot like a tap, if it is, is there any reason to use a tap?

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(12-15-2013, 06:31 AM)Mayhem Wrote: Nice job Mike - you may want to get one of the handles that Ed used when he made his carriage stop.

I cannot recall the name of them but I will be using one when I try my second attempt at a carriage lock for my lathe.

They're called adjustable handles. Here's some examples.

http://www.reidsupply.com/products/knobs...e-handles/

Reid Supply does ship to Canada if you can't find them locally.

Oh, and nice job on the carriage stop. It's a handy accessory to have.

Ed

Posts: 3,795

Threads: 183

Joined: Jun 2012

Location: Farmington Hills, Michigan

Mike,

Be careful power feeding to a hard stop. If you overshoot, you won't be able to disengage the feed (don't ask how I know). On some lathes can be a real pain to replace a shear pin.

Tom

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(12-15-2013, 11:08 AM)TomG Wrote: Mike,

Be careful power feeding to a hard stop. If you overshoot, you won't be able to disengage the feed (don't ask how I know). On some lathes can be a real pain to replace a shear pin.

Tom

And on lathes without a shear pin, like my lathe, I'm sure it's even a bigger pain to replace a gear or gears. And more expensive.

Ed

Posts: 642

Threads: 14

Joined: Oct 2013

Location: East Sussex, UK

That's why I love my Colchester Master 2500. It has an auto knock off against a stop, and you can adjust the force required by twisting the feed lever. I tend to leave a bed clamp firmly fixed just short of the chuck in case I drift off at any time while turning

Andrew

Andrew Mawson, proud to be a member of MetalworkingFun Forum since Oct 2013.

Posts: 3,795

Threads: 183

Joined: Jun 2012

Location: Farmington Hills, Michigan

Andrew,

My Hardinge has an auto stop on the leadscrew. It will repeatedly stop with in couple of thousandths, which is great for threading to a shoulder. The feed has a friction clutch which will slip if it hits a hard stop.

Tom

Posts: 532

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

That's why I use the dial indicator along with the hard stop. I get plenty of warning that the end is near. If I wanted to, i could set the dial for a full inch of warning. On the Hercus, the clutch will slip if it is allowed to hit the hard stop. I haven't tested the new machine. Half-nuts, of course, are a different story.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Hmmm. still no word on the use of a tap as a hard stop???

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)