Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

DaveH (01-18-2015)

Then get your welder out and get cracking Dave

Hunting American dentists since 2015.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

My splitter has a 5/8" thick wedge without any wider "wings". The 2 speed pump moves the wood fast enough that I appreciate the relax time I get out of a full stroke. If my wood popped in two with, say, a 1/3 stroke I wouldn't be able to keep up with it.

I also find that often times although the wood is split apart there strings or threads of wood still holding the pieces together, the full stroke takes care of that.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(01-18-2015, 08:44 AM)stevec Wrote: I also find that often times although the wood is split apart there strings or threads of wood still holding the pieces together, the full stroke takes care of that.

Steve

I get that quite a lot with some woods.

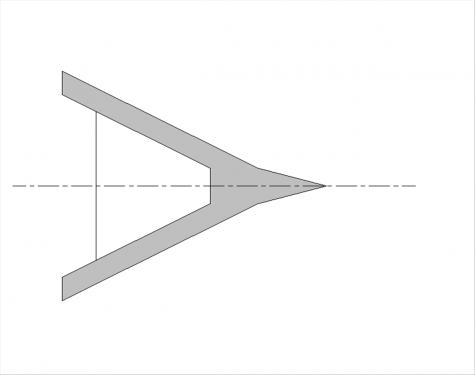

Just going back to the wedge and the shape, I think I will probably make it with straight sides but with a double angle wedge shape.

DaveH

Posts: 205

Threads: 3

Joined: Jul 2014

Location: Vermont

(01-18-2015, 08:44 AM)stevec Wrote: My splitter has a 5/8" thick wedge without any wider "wings". The 2 speed pump moves the wood fast enough that I appreciate the relax time I get out of a full stroke. If my wood popped in two with, say, a 1/3 stroke I wouldn't be able to keep up with it.

I also find that often times although the wood is split apart there strings or threads of wood still holding the pieces together, the full stroke takes care of that.

Steve

Yup, gave up on trying to pull even a few strings apart early on. Wish mine was 2 speed though. Takes a long time to travel all the way to the end. Makes me favor ash over yellow birch! And beech is well named. It's a beech!

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Something like this:

DaveH

I can always take it to a proper welder - it won't cost much.

I can always take it to a proper welder - it won't cost much.