Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Hi Steve,

post # 127 4th photo down.

Normally when there is a gap I end up with weld down each edge and nothing in the middle. Nearly always happens.

DaveH

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 1 user Likes f350ca's post:

EdK (06-27-2014)

Need to wiggle your rod Dave.

If your getting weld on the edges and not bridging Im guessing you might be holding too long an arc? Never seen that.

If your using stick, 7018 or the equivalent wants you almost pushing on the rod, you can't make the arc go out. Keep it submerged and weave back and forth across the gap.

The biggest problem you should have welding the guides on is them wanting to pull to one side as you make the first pass.

Try welding vertical down with the parts positioned as they will be in the press. I get the prettiest welds welding vertical (not that mine are very pretty)

Someone dropped in today with a Honda gas water pump that they hadn't drained and broke out the bottom of the aluminum housing. That was the worst alloy I've ever tried to weld. Refused to flow, just sort of melted itself together. FAR from pretty but may work, told them to try it then come back and pay me if it does't leak too bad.

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

06-28-2014, 05:55 AM

(This post was last modified: 06-28-2014, 06:00 AM by DaveH.)

Thanks Greg,

Mmm ........... With what to have said about the arc length is probably true, I've noticed I start off okay and after about .5 - .75 of an inch the gap appears. On say a weld 1'' long the last .5" - .25" has a gap. So I probably forget to feed the stick in.

I'm not going to weld all the way down the guide (chicken) .5" at the top, bottom and middle. The less welding length I do the less chance I have of making a real mess of it.

On the up side of being a poor welder. I'm really good with the angle grinder

At the end of the day I will get it all "stuck" together just that it will look bluudy awful.

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

06-28-2014, 06:16 AM

(This post was last modified: 06-28-2014, 06:17 AM by stevec.)

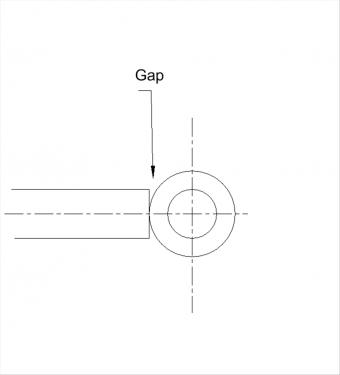

(06-27-2014, 04:25 PM)DaveH Wrote: Steve, have you seen the huge gap between the round guide and the flat part that is welded to it

DaveH

Sorry Dave, I see no welding anywhere on the round guides or the flat part.

post 127 4th down Gap?

Are you talking about the "valleys " not yet welded?

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Steve,

A picture always helps

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Thanks Dave I thought it was that but you had mentioned " that is welded to it " but no welding had been done.

Sometimes I seem to need more clarity than others  .

I know it drives my wife crazy.

I'm sorry you have trouble welding situations like that. I often grind two pieces to be welded to create a gap just like that for maximum penetration and "fill-in".

I use a stick welder for which I've found a rod that works well for me and I won't buy anything else for fear I might loose the moderate success I achieve with it.

I have a wire feed welder that uses flux core wire and have used it for thin metals (sheet metal) but haven't experimented to its full potential

for thicker stuff because my stick welder works for me.

I wish I could help you out but I don't even know where to start.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thank you Steve,

It helps just 'talking' about it   .

DaveH

Posts: 4,368

Threads: 178

Joined: Feb 2012

Location: Missouri, USA

(06-28-2014, 05:55 AM)DaveH Wrote: Thanks Greg,

Mmm ........... With what to have said about the arc length is probably true, I've noticed I start off okay and after about .5 - .75 of an inch the gap appears. On say a weld 1'' long the last .5" - .25" has a gap. So I probably forget to feed the stick in.

DaveH

Dave,

If you are just "forgetting" to feed the rod in at times, perhaps it's time to invest in a MIG welder. It won't forget to feed the wire.

Otherwise, just clean the slag off your weld beads and go back and fill in the gaps. Watch the weld puddle - not the arc. I'm sure your parts are going to hold together just fine.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

06-29-2014, 10:11 AM

(This post was last modified: 06-29-2014, 10:12 AM by DaveH.)

Thanks Willie,

Welded it - not a pretty site  , I'll clean them up then they won't look too bad

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

06-29-2014, 10:18 AM

(This post was last modified: 06-29-2014, 10:20 AM by DaveH.)

Now going back to the springs I may have a fundamental design error

Ed measured the spring wire dia .130" - now if there are 10 turns fully "squashed" makes it 1.30" long. My distance from the lower die plate to the bottom of the guide bush is 25mm.

I made my guide bushes 80mm long.

Ed, Willie, can you please say how long your guide bushes are. I'm thinking they are 3" long,

DaveH

|

.

.

.

.