01-08-2016, 03:18 AM

Gee Rob - you put a lot of time and effort into that lathe just to scrap it.

Well during my recent hiatus from the forum I didn't get a lot of time to really do anything but last weekend I did manage to get some more of my tools organised. I tipped all my fractional taps out of the old ammo case they weredumped placed into and organised them by size and form.

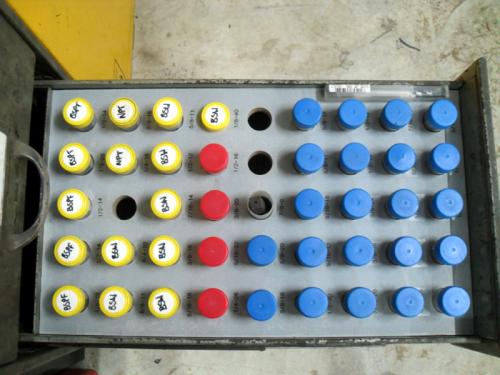

I then drilled some 30mm holes into some MDF, which I then screwed into a small filing cabinet draw. The 30mm size is perfect for the centrifuge vials that I now store them in.

Blue tops are UN, Red are BSF and the Yellow are a mix of BSW, BSPF (or BSPP depending on which one you prefer to use), BSPT and NPT. The 7/8-9 UNC tap is just a little too long to get the cap to screw on and the 1/2" UNF Spiral bottoming tap is simply too long to stand up in the drawer, which is why it is laying down.

The three spare holes are there in case I get any additional size/form taps. I just hope I don't need to buy four

Well during my recent hiatus from the forum I didn't get a lot of time to really do anything but last weekend I did manage to get some more of my tools organised. I tipped all my fractional taps out of the old ammo case they were

I then drilled some 30mm holes into some MDF, which I then screwed into a small filing cabinet draw. The 30mm size is perfect for the centrifuge vials that I now store them in.

Blue tops are UN, Red are BSF and the Yellow are a mix of BSW, BSPF (or BSPP depending on which one you prefer to use), BSPT and NPT. The 7/8-9 UNC tap is just a little too long to get the cap to screw on and the 1/2" UNF Spiral bottoming tap is simply too long to stand up in the drawer, which is why it is laying down.

The three spare holes are there in case I get any additional size/form taps. I just hope I don't need to buy four

Hunting American dentists since 2015.

![[Image: 2h826j4.jpg]](http://i64.tinypic.com/2h826j4.jpg)

![[Image: wtbts7.jpg]](http://i68.tinypic.com/wtbts7.jpg)

![[Image: 33e372q.jpg]](http://i64.tinypic.com/33e372q.jpg)

![[Image: 2s6re3s.jpg]](http://i66.tinypic.com/2s6re3s.jpg)

![[Image: fdrfw9.jpg]](http://i63.tinypic.com/fdrfw9.jpg)

![[Image: 2djzyjb.jpg]](http://i65.tinypic.com/2djzyjb.jpg)

![[Image: 1zyh5lf.jpg]](http://i65.tinypic.com/1zyh5lf.jpg)

![[Image: v74b2r.jpg]](http://i64.tinypic.com/v74b2r.jpg)

![[Image: 2078bkp.jpg]](http://i63.tinypic.com/2078bkp.jpg)

![[Image: 2cngxap.jpg]](http://i68.tinypic.com/2cngxap.jpg)

![[Image: 10ehurr.jpg]](http://i66.tinypic.com/10ehurr.jpg)

![[Image: 2ai0i1v.jpg]](http://i64.tinypic.com/2ai0i1v.jpg)

![[Image: 2d0mhk8.jpg]](http://i64.tinypic.com/2d0mhk8.jpg)