Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(09-27-2012, 07:10 AM)stevec Wrote: This is probably machining heresy and/or suicidal but I have shaped rounded ends on rectangular parts by drilling a hole in the centre of the end for a pivot pin which is held in the mill vise. Feed the vise toward the end mill and turn the part with your other hand. Take small cuts and DO NOT CLIMB CUT! Start at the apex of the corner you want to round off so as not to cut too deep as you're arcing the part into the side of the endmill. once the radius is done to your liking back off and flip the part over for the other side, If the part isn't long enough to be safely held by hand , hold it with vise grip pliers the added landth gives mechanical advantage and better control.

A better pivot pin would be one threaded for a lock nut to keep the part from lifting.

For large radii I rough cut excess metal off on the bandsaw to reduce milling time.

Steve,

That's a commonly used technique and certainly not heresy. Another tip is to add stops so you don't overshoot your arc.

Now that you mention using your bandsaw to cut off the excess, that's what I did with the small wrenches I made. Then I hand filed the OD radius at the business end of the wrench.

Ed

(09-26-2012, 09:30 PM)TomG Wrote: Mike,

If you are going to the trouble of making a tool, go the extra mile and harden it. It'll hold up better for its intended use and it won't get all beat up from getting knocked around. You can either make it out of O1 to begin with and then harden and temper it with a torch, or you can save some money and make it out of mild steel and case harden it afterward. Either way you'll end up with a much nicer tool.

Tom

Tom,

Details, please! By "mild steel" is there a specific number you mean? I use Online Metals for supply, since they are 10 minutes from me. And how do I case harden?

Oh, joy! New things to learn!

Posts: 3,795

Threads: 183

Joined: Jun 2012

Location: Farmington Hills, Michigan

(09-27-2012, 09:32 AM)Wawoodman Wrote: (09-26-2012, 09:30 PM)TomG Wrote: Mike,

If you are going to the trouble of making a tool, go the extra mile and harden it. It'll hold up better for its intended use and it won't get all beat up from getting knocked around. You can either make it out of O1 to begin with and then harden and temper it with a torch, or you can save some money and make it out of mild steel and case harden it afterward. Either way you'll end up with a much nicer tool.

Tom

Tom,

Details, please! By "mild steel" is there a specific number you mean? I use Online Metals for supply, since they are 10 minutes from me. And how do I case harden?

Oh, joy! New things to learn!

Mild steel is anything that contains too little carbon to harden on its own, 1018 is a good example. To case harden, you heat the part to a dull red and dip it in a carburizing compound (Kasenit is a common brand) then re-heat it to a cherry red color and hold the temp for a few minutes to allow the carbon to soak in, then water quench. The cherry red is the key here (around 1400º). Overheating can warp or damage the tool. Another good way to check for the proper temp is to use a magnet. Mild steel becomes non-magnetic at the critical stage.

Case hardening works well for tools because only the surface gets hard. The tool gets strong and durable but it doesn't get brittle.

Tom

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)

Posts: 258

Threads: 13

Joined: Aug 2012

Location: USA

Why not make the wrench just have a hex like a big nut? That seems like it would be easier and I think it would still look good. Just a thought.

SnailPowered, proud to be a member of MetalworkingFun since Aug 2012.

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(09-27-2012, 11:13 AM)SnailPowered Wrote: Why not make the wrench just have a hex like a big nut? That seems like it would be easier and I think it would still look good. Just a thought.

I'm not sure I quite follow what you're saying but these wrenches are for a wood router which typically needs two wrenches to tighten and loosen the collet nut. One wrench to hold the spindle from turning and one on the collet nut. They need to be fairly thin because you don't have a lot of room in a router to get the wrenches in there to do their job.

Clear as mud?

Ed

Posts: 258

Threads: 13

Joined: Aug 2012

Location: USA

I don't mean to use a nut for the wrench, I mean to have a hex shape where it would normally be rounded (you would have three flats on each side instead of a radius). Sorry, I guess I was clear as mud

SnailPowered, proud to be a member of MetalworkingFun since Aug 2012.

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(09-27-2012, 11:40 AM)SnailPowered Wrote: I don't mean to use a nut for the wrench, I mean to have a hex shape where it would normally be rounded (you would have three flats on each side instead of a radius). Sorry, I guess I was clear as mud

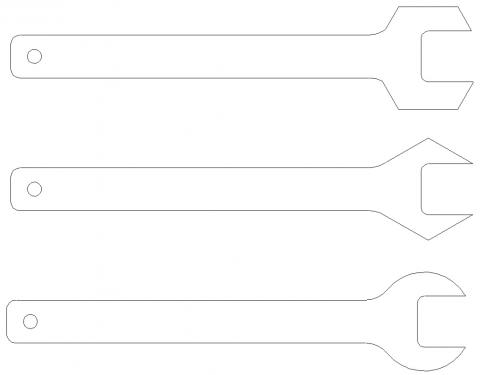

Ah, OK, now I think I know what you're saying. Like one of the top two in the image rather than the bottom one which is rounded.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

carbide cutters and old lawn mower blades

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 8,739

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(09-27-2012, 11:55 AM)dallen Wrote: carbide cutters and old lawn mower blades

David,

Now that's a great use for old lawn mower blades. Thanks for that tip!

Ed

Posts: 258

Threads: 13

Joined: Aug 2012

Location: USA

09-27-2012, 12:10 PM

(This post was last modified: 09-27-2012, 12:11 PM by SnailPowered.)

That's EXACTLY what I was thinking Ed. The top one is basically what I had in mind, the second one I would end up hurting myself with

Thanks!

SnailPowered, proud to be a member of MetalworkingFun since Aug 2012.

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)