Posts: 1,459

Threads: 159

Joined: Feb 2012

Location: Northern England

Posts: 8,746

Threads: 314

Joined: Feb 2012

Location: Arizona/Minnesota

John,

Me too. At first I thought I would need at least one collet to install the chuck on the lathe just to measure run-out. After smacking myself in the head a few times I realized I can, and should, indicate off of the ER taper on the collet chuck. So now I don't need to wait for the collets to arrive before I begin the project.

Ed

Posts: 8,746

Threads: 314

Joined: Feb 2012

Location: Arizona/Minnesota

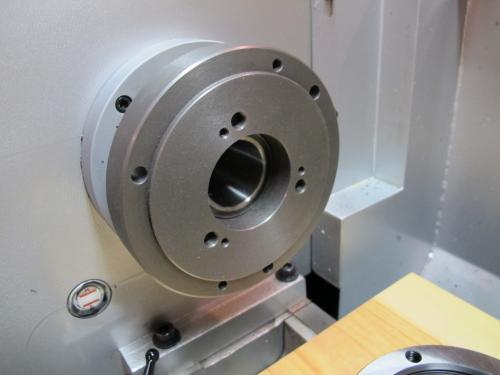

OK, here is what I've got so far. D1-4 cam lock adapter plate installed on the lathe.

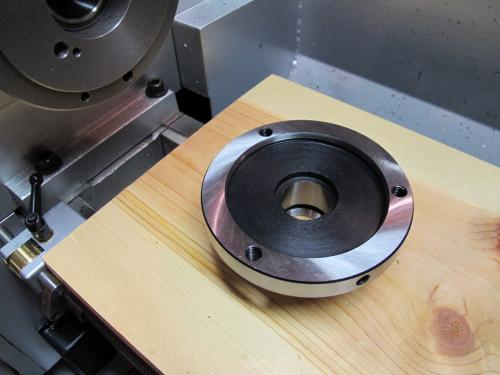

ER-40 chuck that needs to be attached to D1-4 adapter plate.

I marked the pin location on the D1-4 adapter plate so I can put it back on the spindle the same way each time.

I assume my next step is to turn down the adapter plate for a snug fit to the recess on the back side of the ER-40 chuck. Agreed?

Ed

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

09-07-2012, 08:23 PM

(This post was last modified: 09-07-2012, 08:27 PM by PixMan.)

Agreed!

Make sure you take at least a clean skin chip off the face too, for assurance of both radial and axial runout being minimal.

Machine the OD so the collet chuck is a very snug fit at first. Check runout of the ER taper at that fitment, and if it's not true you'll need to take off the equivalent of 2X the measured runout to have enough clearance to "tap it in" to true before you really clamp it down.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Ed,

I'm just wondering is the collet chuck hardened?

DaveH

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

It should be somewhat hard, in the 42Rc to 48Rc range, for wear resistance. You don't want it much over 50Rc because it could shatter like glass if you had an "oops". That would be disastrous with a rotating chuck.

Ed, your lathe looks new are you just starting to get it tooled up? Good project , waiting on the results

Posts: 8,746

Threads: 314

Joined: Feb 2012

Location: Arizona/Minnesota

(09-08-2012, 07:26 AM)DaveH Wrote: Ed,

I'm just wondering is the collet chuck hardened?

DaveH

Dave,

I assume it has to be somewhat hard to take the wear but I don't know exactly what hardness it is. I got it from Jeff at tools4cheap.net and he has a reputation for selling good stuff so I think it should be a good quality tool.

Ed

Posts: 8,746

Threads: 314

Joined: Feb 2012

Location: Arizona/Minnesota

(09-08-2012, 08:07 AM)pineyfolks Wrote: Ed, your lathe looks new are you just starting to get it tooled up? Good project , waiting on the results

Piney,

No, the lathe is not new. I got it a little over three years ago. It's pretty well tooled up for my needs. I just didn't have a collet system for it so I got the ER-40 collet chuck for it. I also plan on making a 5C collet closer for it so I can also use my 5C collets on it also.

Ed