Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Greg- those variable diameter pulleys have always seemed to me like a brilliant thing. A question- does the whole mechanism float freely on the shaft so that it self-aligns as the gap varies? Also, does this one use a normal belt? I saw one the drive of a skid-steer loader a few years ago and it had a belt that was about 2" wide, only ever seen one other and it was not mounted in a machine so never saw the belt.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

The pulley is fixed to the shaft, usually the designers don't worry about the alignment. My Rockwell wood lathe, Hardinge lathe and the Logan shaper I had used two belts with the pulley in the middle having a floating centre. That system gives a huge ratio range, but the belts ran on a slight angle as the position of the centre pulley changes.

On this OLD Delta saw, (found a brochure form 1944) on it they have the motor mount slide in an angled mount to compensate for the change in angle. Oh yah this uses a standard with belt as did the Rockwell and Logan, the Hardinge uses a v-belt about an inch wide.

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

The following 2 users Like EdK's post:

Mayhem (10-22-2016), aRM (11-06-2016)

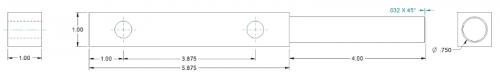

Worked on a work stop for my Kurt vise. Just got the shaft turned. It took a while to turn because of the interrupted cut. I didn't want to push it too hard and chip the carbide tool.

Ed

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

The following 1 user Likes Roadracer_Al's post:

f350ca (10-23-2016)

I usually switch over to HSS tools to rough out jobs like that, then switch back over to carbide to do the finishing passes.

I use a roughing tool grind that I saw on Adam Booth's channel, but can't seem to find it.

It's flat on top (i.e. no top relief), has some front relief and side relief (actually, not much, only about 5° to create a strong cutting edge) and a small 45° chamfer with relief on the leading corner of the tool to keep the edge from breaking down. He also cuts a chip breaker into the top using the corner of the wheel. The chip breaker doesn't come to the edge - it's about 1/16" back from the edge. I believe it works to chill the underside of the chip, making it break.

It's a beast of a tool - I've cut .25" DOC (1/2" diameter reduction) on mild steel with it. It requires not only a short grip on the work, but also a shoulder bearing against the chuck jaws or it will just extrude the work through the jaws. It also requires lots of lube, some HP, and low RPM for a big cut like that.

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

(10-23-2016, 04:13 PM)Roadracer_Al Wrote: I usually switch over to HSS tools to rough out jobs like that, then switch back over to carbide to do the finishing passes.

That's normally what I do also but I couldn't find my HSS tool bit so I just used what I could find.

Ed

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

10-24-2016, 04:57 PM

(This post was last modified: 10-24-2016, 05:01 PM by Old Minger.)

I finally put together this little vice that i found on CL for $20 and yes It's not a coincidence that this is the same colour as my Bridgeport mill restoration project. While the paint was flying everything got a coat of grey.

Still have to make some soft jaws for it, if only I had a milling machine!

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Mayhem (10-24-2016)

(10-24-2016, 04:57 PM)Old Minger Wrote: Still have to make some soft jaws for it, if only I had a milling machine!

If you send me the dimensions, I'd be happy to make the soft-jaws for you.

Ed

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

The following 3 users Like Old Minger's post:

EdK (10-25-2016), DaveH (10-25-2016), Mike E. (11-12-2016)

Thanks Ed, that's really kind of you.

I'll go and have a measure up and send you the dimensions.

If you could make them out of something soft like ... 18ct gold that would be awesome

Cheers

John

Posts: 2,596

Threads: 99

Joined: Dec 2014

Location: Michigan

The following 2 users Like Vinny's post:

EdK (10-25-2016), Mike E. (11-12-2016)

I think he only stocks 24ct gold.

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

(10-24-2016, 05:12 PM)EdK Wrote: (10-24-2016, 04:57 PM)Old Minger Wrote: Still have to make some soft jaws for it, if only I had a milling machine!

If you send me the dimensions, I'd be happy to make the soft-jaws for you.

Ed

PM sent.

|