Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

They look a little on the cool side Dave, the welding may say its at 95 but who knows, the current on the box is kind of like a speed limit sign, thats only a suggestion. Crank it up till you start to see some undercut at the edges of the weld, then drop back a bit, or leave it there and fill it in better. Unless your blowing through your good to go.

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thanks Greg,

I have to say it is not the first time it has been suggested my welds look a little cold.

DaveH

Posts: 4,438

Threads: 183

Joined: Feb 2012

Location: Missouri, USA

Dave, yes you can try cranking it up a bit more and try that. You may end up getting a lot of spatter though. The thing is the type of flux on the 6010 rods allows your weld puddle to "dig" in better and get down into the root of your material more and wet out better. The flux on the 6013 rods is designed to prevent that, and keep it from burning through your material. It allows the puddle to cool faster and "freeze" the bead sooner which is a good thing for filling gaps.

6010 was designed to run on DC polarity, and later on they came up with 6011 that will run on AC polarity. Looking back now at your machine, it looks to be DC only.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

That's correct Willie, my machine is DC. I have tried it with the connections reversed - didn't make much difference to my welding

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

06-20-2014, 08:25 AM

(This post was last modified: 06-20-2014, 08:35 AM by DaveH.)

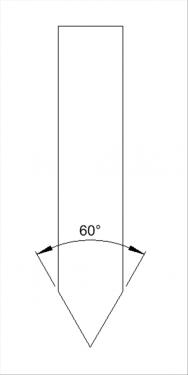

The top die. This is 4" high x 16" long x .75" thick, and on one of the 16" long sides I have to machine a double chamfer 60 or 70deg (included) point.

Normally with long pieces I use two vices, however these two vices do not tilt. I have another vice that does tilt but only the one vice.

Anyone have an idea how I should do this?

DaveH

Posts: 4,438

Threads: 183

Joined: Feb 2012

Location: Missouri, USA

Dave, do you by chance have an indexing head w/4 jaw chuck?

Or you could put your woodworking skills to use and build a v-block / fixture from lumber to hold the part at the proper angle and clamp the whole works to the table.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(06-20-2014, 10:57 AM)Highpower Wrote: Dave, do you by chance have an indexing head w/4 jaw chuck?

Or you could put your woodworking skills to use and build a v-block / fixture from lumber to hold the part at the proper angle and clamp the whole works to the table.

I have an indexing head with a 4 jaw chuck. I was thinking about using the tilting vice one side and using a rotary table to hold the other end.

I didn't really want to make any fixtures - being the lazy bastard I am

I'm just a bit concerned about the length and it flapping about in the breeze.

A couple of tilting tables would be nice

which I haven't got

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

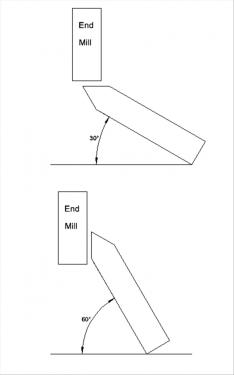

I can hold it at a shallow angle or a steep angle. If I was using just the tilting vice I would tend to hold it at the steep angle and use the side of the end mill.

DaveH

Posts: 4,438

Threads: 183

Joined: Feb 2012

Location: Missouri, USA

(06-20-2014, 11:27 AM)DaveH Wrote: I have an indexing head with a 4 jaw chuck. I was thinking about using the tilting vice one side and using a rotary table to hold the other end.

I must have been reading your mind then.

Just put some machinist jacks or blocks under the part to support it between your vice and indexing head.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Of course I could just use the tilting vice and "wing it"

May be if I roughly cut the 'V' out to start with and then just hold it with the tilting vice and take light cuts on the milling machine. Perhaps it's worth a shot

It will either work or it won't.

DaveH

which I haven't got

which I haven't got