Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Thats somewhat like mine Dave. The leading edge is slightly longer and more slender on mine, thats where the wood gets stuck.

If you go with that design, extend the centre part through to the back, weld it to the beam first then add the wings. More surface to weld.

Free advice is worth exactly what you payed for it.

Greg

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(01-18-2015, 10:39 AM)f350ca Wrote: The leading edge is slightly longer and more slender on mine, thats where the wood gets stuck.

Greg, I'm not sure I understand that. "longer and more slender on mine, thats where the wood gets stuck. ".

Does it get stuck at the "flare out" to the wider angle.

I don't ever remember seeing a splitting axe being advertised with a wide continuance to the initial wedge.

I could be wrong (slap! no, not possible!)

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

We're never wrong Steve just misunderstood.

Not a great picture (sure was shiny back then). You can see the thin cutting edge protruding about an inch ahead of where the wedge spreads out. That will cut into the wood easily, if the block doesn't start to split at that point she's stuck. Sometimes really stuck. But I'm only using a single stage pump with the relief set at 1800psi and a 3 1/2 inch cylinder, about 8 1/2 ton force.

![[Image: 107-0705_IMG.jpg]](https://lh5.googleusercontent.com/-OZmNJNtI800/T5NHgHllOoI/AAAAAAAAAVw/A0kcFvEhkiU/s1280/107-0705_IMG.jpg)

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Nice log splitter Greg

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

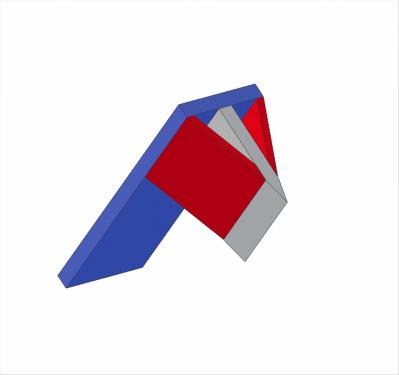

Just to help this is what the wedge will look like.

Although it will look like it has been in a war when I finish welding it

The grey part is the primary wedge 30 deg inc

The red 'wings' provide the secondary wedge 50 deg inc

The blue part is the back plate and is further welded to the I beam (not shown)

Also some 'strengtheners' between the grey part and the red parts (not shown)

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

I have the same problem what Greg has when splitting logs, especially if the logs are wet the first part of the wedge goes in deep but the log does not split. Obviously if one uses enough force it may not split the log but it will be 'sliced' in two

In my case I am going to allow the logs to dry out.

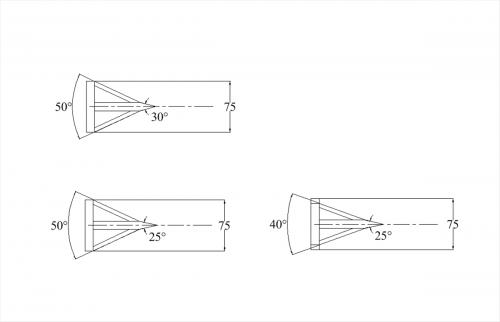

Nevertheless it does seem a good design to help split the logs with an increase in the angle of the wedge, on commercial ones the wedge is curved.

![[Image: attachment.php?thumbnail=9889]](http://www.metalworkingfun.com/attachment.php?thumbnail=9889)

Now they must have a good reason for doing it and the nice thing about the curve the angle of the wedge increases the further the log is pushed on.

May be I should look at a curved wedge.

At the moment I'm not sure what angles to use on the primary and secondary wedge angles.

Maybe I'm looking too deep .............. it's a log splitter

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

"I have the same problem what Greg has when splitting logs, especially if the logs are wet the first part of the wedge goes in deep but the log does not split."

That's one of the reasons I didn't "flare" my wedge. All logs get split wet, dry, hot, cold, old or young.

Another reason is if my logs split sooner in the stroke I'd have a harder time controlling them, a potential for injury (like pieces falling on my feet.)

My splitter has a tray just beyond the wedge that allows my to control them for further splitting if required or place them in the wheel barrow for transfer to the stacking operation.

My wedge is pinned in a "socket" in the beam and can be removed and replaced with a "cross" wedge or even 6 way "star" although I have not made any yet, it may come about once I get/build a conveyor to replace the wheel barrow.

I'd post a pic of my "removable" wedge but I don't know how to make it an "URL" to post it.

Steve

[img]http:://www.metalworkingfun.com/C:\Users\Owner\Pictures\2015-01-20\P1200001[/img]

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Steve if the URL is your computer I don't think you will able to place the image on here.

Just save the image as a .jpg on your computer and then post it here.

Use the

Attachment part in the post reply screen.

Click

Browse button find your image in the opened box click it then click the

open button. Then click

Add Attachment ........... wait for it to up load then click

Insert in to post. In you posy you will see [attachment = 1234] You can delete in your post and place somewhere else if it is in the wrong place by deleting and click I

nsert in to post . Delete it in your post

do not use remove.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(01-20-2015, 09:07 AM)stevec Wrote: That's one of the reasons I didn't "flare" my wedge. All logs get split wet, dry, hot, cold, old or young.

Steve

Steve,

Mine and Greg's are low force under 10 tons log splitters, I think once you get to 20 tons the flared wedge isn't needed. (I think maybe

)

DaveH

![[Image: 107-0705_IMG.jpg]](https://lh5.googleusercontent.com/-OZmNJNtI800/T5NHgHllOoI/AAAAAAAAAVw/A0kcFvEhkiU/s1280/107-0705_IMG.jpg)