Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Ah! Stringy! That's precisely why I recommend a thin wedge (no spreader wings) and a full stroke.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(01-22-2015, 06:58 AM)stevec Wrote: Ah! Stringy! That's precisely why I recommend a thin wedge (no spreader wings) and a full stroke.

Steve

I think most will agree with you there Steve. (Well I do

).

So at the end of the day it seems "horses for courses", and it is doubtful one wedge (wedge shape) will do for all purposes.

I also know it takes more force for a thick wedge than a thin wedge to a given depth assuming everything else is the same.

So why are these small (under 10 ton) commercial log splitters using a wide wedge?. Why does my 6ton log splitter use a wide wedge, they have gone to a lot of trouble to do it? - They must have a reason.

Could it be nothing to do with splitting the wood but more on welding the wedge over a bigger area thereby minimizing the chances of a catastrophic failure ?

Any thoughts

DaveH

Posts: 121

Threads: 4

Joined: Dec 2014

Location: Germany/Kandern

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

I understand what you are saying BF but on the larger log splitters (commercial more than 15 tons) it seems very rare to see these wider wedges even though they start talking about quick recycle times.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

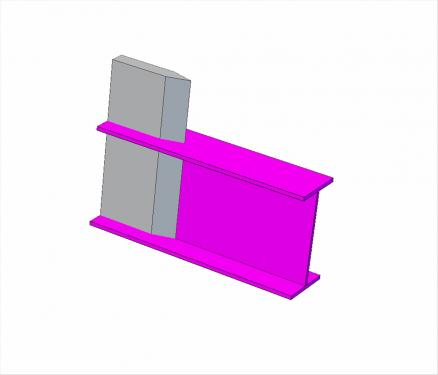

Back to the beginning of fixing the wedge to the I beam.

Cut a slot in the top of the I beam and remove the web down to the lower flange and weld the wedge in.

Even my poor welding should be good enough to hold it.

Something like this. I'll also weld in a backplate. - Now where's the angle grinder?

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Like the work bench Dave

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

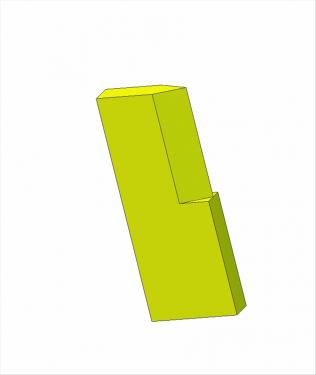

This is the wedge

255 (10") long

100 (4") wide

25 (1") thick

The wedge 'pointy bit' is 125 (5") long and 40deg inc. No idea what the angle should be so I took a stab in the dark

DaveH

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 2 users Like f350ca's post:

stevec (01-27-2015), EdK (01-27-2015)

Think they have to be 40.25 deg to work at all.

Free advice is worth exactly what you payed for it.

Greg

).

).