Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

I also have to look at it from a sensible practical point of view.

I'm good looking and intelligent therefore I have no chance of becoming a 'good welder'.

The more welding used on the parts that are 'stuck' together the better chance I have of it staying 'stuck' together.

Something held together with just a few inches of weld isn't going to work for me

DaveH

Posts: 205

Threads: 3

Joined: Jul 2014

Location: Vermont

01-30-2015, 10:56 AM

(This post was last modified: 01-30-2015, 10:57 AM by vtsteam.)

The 1 horse powered splitter has a very interesting capability -- anybody notice?

Look at the split and retract speed. That has it all over my hydraulic splitter. I'm wondering what the mechanism driving the ram is -- friction, rack and pinion?

A machinist friend in New Hampshire has a screw driven splitter that he's had for 15 years. At the time he bought it, it was more expensive than an hydraulic splitter.

He swears by it. I haven't seen it myself, but he said the retract speed and his throughput is much greater than a hydraulic splitter. He splits about 10 cords a year for his own use, and also splits wood for his mother.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

The following 2 users Like DaveH's post:

EdK (02-01-2015), Highpower (02-01-2015)

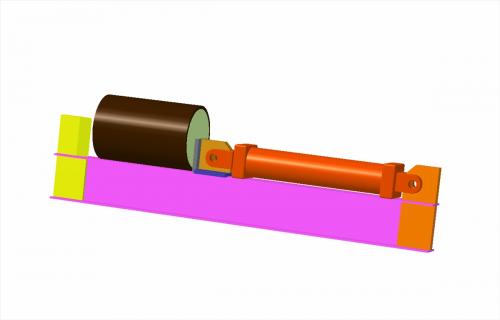

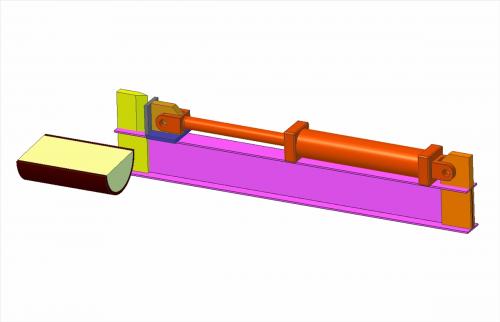

I was asked why I do these 3D sketches and why the 'silly' colours.

Well I do them because I can

also I enjoy doing them I find it fun.

As for the colours I don't have one of those 'photo realistic' programs

a little on the expensive side for me.

So I use whatever colour I fancy just to show the different components.

Being as you all like them so much here's some more

Ready to split a log

Look at the nice job it did splitting that log

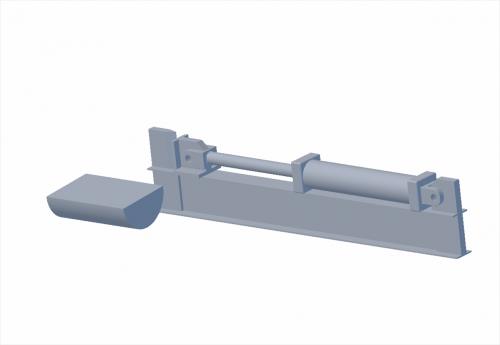

Here's one all grey ................ boring!

DaveH

a little on the expensive side for me.

a little on the expensive side for me.  So I use whatever colour I fancy just to show the different components.

So I use whatever colour I fancy just to show the different components.