Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

(06-11-2015, 08:51 AM)dallen Wrote: (06-11-2015, 02:14 AM)Pete O Wrote: The casing of the worm gearbox is also cracked, presumably from someone trying to force movement in the Y axis after the shaft seized, so i will have to either weld it or make a new one (who do I know who has an iron casting furnace...)

If your not able to do it yourself (Casting Iron is a whole new level of learning) I would try to get ahold of a guy on yourtube by the handle of

https://youtu.be/WERgTZvfnbw

He's in Oz not sure where, but if it was me I would try to contact him thru one of his videos and see if he would do it. I could but the shipping would be a killer I'm sure.

If the cracks aren't too bad it would be welded, or brazed. do you have a photo of the cracked area?

Dallen my comment about the furnace was sort of tongue-in-cheek, as I'm in the process of building one that will hopefully be capable of meting iron. I hear you about the level of learning though, I have never cast anything whatsoever. If I manage to get the worm gearbox out this afternoon, I'll be able to better assess the amount of damage to the casing as well as whether I can get the seized shaft out of the worm gear without destroying the gear.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

I removed and dismantled the worm drive gearbox this afternoon. I think the shaft is actually bent inside the worm gear, as the outer end of the shaft is unsupported it wouldn't take much to bend it, perhaps lowering the knee with something uner it or something like that, then the gear has been forced over the bent section of shaft by screwing the Y feed in. Here's the contents of the gearbox:

It all seems to be undamaged, except for where the shaft has been cut at each end. Here's the worm gear with the shaft jammed inside it:

I heated the gear gently with a propane torch to see if I could get the shaft out, I can get it to move maybe 3/16" either way but that's it, don't want to force it and damage the gear. I have a plan for getting it out, would appreciate some feedback on whether this approach is likely to bear fruit; if I chuck it in the 4-jaw with some soft jaws gripping the large diameter of the worm gear, face the damage shaft and then centre-drill it, drill it out to almost the full depth of the gear, making a blind hole, gradually increasing drill size until I cut through into the keyway, then use a punch to drive it out. With the shaft drilled out to the keyway, it should be able to collapse as it is driven out, hopefully not damaging the bore of the worm gear.

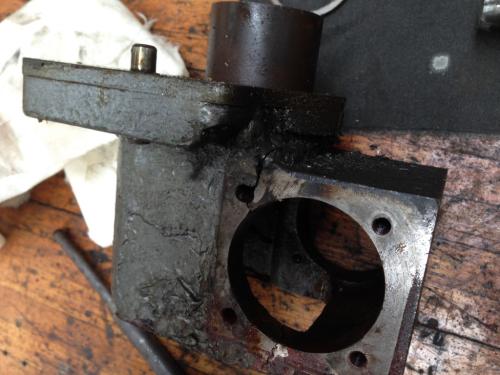

The gearbox casing is a concern, I think it is beyond welding:

Someone has already had a go at it:

I'm open to opinions, but I reckon this is not going to be repairable. It is cracked through both bores.

Thinking about casting a replacement, is there any reason why I could not do it in aluminium?

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

06-12-2015, 07:46 AM

(This post was last modified: 06-12-2015, 07:50 AM by dallen.)

it could be done in Aluminum, Cast Iron was the casting metal of choice for most things casted back when this was made. They cast all sorts of gear boxes out of aluminum nowdays.

With a vertical mill and the old box as a pattern, and a big hunk of Aluminum you could mill out a nice shiny new one in probably less time then it would take to make a pattern and core box then get the thing poured and machined out.

Hard to tell from the photos but if it fits on the mill like it should, a person could take it and heat it up hot enough to burn all the oil and grease out of the metal and relieve any stresses, and with the inside of the crack already Vee'd out prio to heating weld the inside up with some NiCast rod .

that's the X axis feed screw, I'd say its more likely damaged by someone putting a lifting strap where it shouldn't of been

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 716

Threads: 32

Joined: Apr 2012

Location: Washington, USA

It doesn't look like it's going to fall apart. I'd be inclined to bore the holes round again and either sleeve them back to size or bush directly. Fill the cracks with epoxy to seal them. Your plan for the worm sounds like a good one.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

The following 1 user Likes Pete O's post:

f350ca (06-14-2015)

The plan for removing the stuck shaft from the worm gear worked a treat, gripped the worm gear in some makeshift soft jaws (some strips of 2mmx x20mm aluminium flat bar between the chuck jaws and the workpiece), drilled out to 5/8" which was just starting to break through the base of the keyway. Then used a punch and bush to drive the shaft out, came out very easily. You can see here a section where it has galled badly, I'm thinking perhaps a chip got carried into the bore, anyway not much point trying to guess what happened, it is what it is and just has to be put right.

There is of course a corresponding galled section in the bore of the worm gear, nothing a bit of a hone can't cure I'm sure. I'm much happier with the stuck shaft out of this and the gear intact.

You guys have given me some heart that the gearbox housing may be salvageable, I'm thinking it can wait until my furnace is finished and I can cook the oil out of it then weld it. In the meantime the mill will be operable but without any power feeds, better than no mill at all by a long way.

In the meantime I'll shop for some shaft steel as suggested, weld a thick disc onto it for the flange, I'm thinking I can mount the shaft between centres and use a dial indicator to check for deformity once the flange is welded on, keep adding a bit of weld to the outside of the bend until it's straight again.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

The following 3 users Like PixMan's post:

Mayhem (06-13-2015), EdK (06-13-2015), Pete O (06-14-2015)

You know Pete, it occurred to me that if repairing the cast gearbox housing isn't a viable option, most people in Australia just send the part off to a shop up in the northeast US and a new, machined from solid piece is sent back. Eventually.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 2 users Like Mayhem's post:

EdK (06-13-2015), PixMan (06-13-2015)

(06-13-2015, 06:37 PM)PixMan Wrote: You know Pete, it occurred to me that if repairing the cast gearbox housing isn't a viable option, most people in Australia just send the part off to a shop up in the northeast US and a new, machined from solid piece is sent back. Eventually.

Personally I'd never do that without inspecting the shop and the staff first. You can never be too sure of who you are sending it to. Of course, you then have to make periodical checks, to ensure that the standards are maintained

Hunting American dentists since 2015.

Posts: 8,741

Threads: 313

Joined: Feb 2012

Location: Arizona/Minnesota

I can vouch for what Ken said. And the quality is top notch.

Ed

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

(06-13-2015, 06:37 PM)PixMan Wrote: You know Pete, it occurred to me that if repairing the cast gearbox housing isn't a viable option, most people in Australia just send the part off to a shop up in the northeast US and a new, machined from solid piece is sent back. Eventually.

If I'm to understand this as an offer, it is incredibly generous. Despite what Darren says.

I'm going to struggle to get any time on this thing for a few weeks as I'm taking my wife away on an outback trip for a fortnight and have to get a few jobs done on the vehicle to be ready for the trip, leaving probably Friday so that has to take priority for me this week although it's killing me having the mill sitting there and not yet running. Just picked up a 7.5 hp motor to use as an idler for my rotary phase converter, the friend who is sourcing other components for me (transformer and capacitors etc) is away this week so there's not even any prospect of getting the motor spinning before we go away.

When I can get another block of time on the mill, I'll see if I can make an assessment of just how repairable or not the gearbox is and whether it might be necessary to send it on a world tour.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(06-14-2015, 03:06 AM)Pete O Wrote: If I'm to understand this as an offer, it is incredibly generous. Despite what Darren says...

Pete - my comments were totally tongue in cheek, as I have been the main beneficiary of Ken's generosity. I've had the pleasure of working on several of my projects in his shop, whilst in the US on business. I've also sent poor quality drawings to him and received top quality parts in the post.

My Kondia mill certainly wouldn't be running now without Ken's assistance in making some obsolete parts

Hunting American dentists since 2015.

|