Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

I've discovered that there is a shaft missing from the drive system on my new (old) milling machine, looks like there has been a part seize on the shaft due to neglect of lubrication in a small gearbox, which has meant that the seized part of the shaft has been cut and the remainder removed. Looking at the system that the shaft is part of and the exploded diagrams, it shouldn't be difficult to make a new shaft but I'm wondering what material I should use. I'd like to provide some photos but as it is difficult to photograph something that is missing, I'll try to describe the shaft and it's function as best I can.

Over most of it's length it is around 3/4" in diameter, approx 18" long, with a few features machined into it. It is driven by a pinned drive dog at one end (this is a 5/16 brass shear pin that provides a weak link for protection of the drive train), then passes through one small gearbox (the Y and Z axis drive gearbox) where it runs in a bronze bush at either end and has one small spur gear that will be woodruff keyed onto the shaft, with an external circlip that holds that gear in position at the far end of the gearbox. Where the shaft exits that first gearbox, it will have a flange of approx 1.5", which runs in thrust against the bronze bush to prevent the shaft moving back toward the drive end. The remainder of the shaft is a constant diameter with a long keyway, this part of the shaft runs through a second gearbox with a bearing at either end, inside this second gearbox the shaft drives (via the long keyway) a worm gear for the X-axis drive. This worm gear needs to be able to slide along the shaft, with the long keyway, whilst being driven- the gearbox moves in Y with the table, sliding along the shaft whilst receiving drive for the table's X movement.

So a summary of the shaft; firstly a cross-pin hole to drive it, then running in a bronze bush, a circlip groove, a woodruff keyway driving a gear, a second bronze bush, a flange, then a long keyed section driving a sliding worm gear.

I'm hoping for some advice on the best choice of material for this shaft, and whether it should be case hardened or some other process once it is made. The whole shaft will need to be machined from stock bar with a diameter at least equal to that of the flange (approx 1.5"), but should be a fairly straightforward machining job. I expect the woodruff keyway and the other long keyway will be the first tasks for the mill itself, will be relying on manual feed in all axes until i can get this part made and installed.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Could you post pictures of what is there as well as the exploded diagram?

Hunting American dentists since 2015.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

Pete, I'd check the existing shaft with a file to see if it is hardened, chances are its not.

Can the flange be added? Maybe heat shrink or weld a section on before final machining. I felt I had to machine the shaft for the chain saw Im building out of a solid section, the flange on it is 2 inch dia and the rest of the shaft just over inch but the flange carries all the torsional load of about 10 hp at 7600 rpm. In your case i'd weld it up then machine.

As for material, maybe my go to 4140 annealed for a project like that. Good strength , weldable and relatively easy to machine.

Free advice is worth exactly what you payed for it.

Greg

Posts: 716

Threads: 32

Joined: Apr 2012

Location: Washington, USA

06-10-2015, 09:25 AM

(This post was last modified: 06-10-2015, 09:38 AM by Sunset Machine.

Edit Reason: Added link to 1045 TGP

)

It doesn't sound like something that has been hardened. Take a file to things and see, and look for signs of grinding. If it's hardened you want, then try the 414x HT/PH/"half-hard" series. Something easier to work might be Stressproof. It doesn't seem to resist twisting very well, but it might be just the ticket for this.

http://www.speedymetals.com/information/Material63.html

http://www.speedymetals.com/information/Material37.html

http://www.speedymetals.com/information/Material32.html

I wouldn't want to turn an expensive bar of 1-1/2" whatever down to 3/4". f350ca is right-on with his suggestion of a weldment if you can make it work.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

As Darren requested, some photos of what is there, and I'll see if I can upload a page from the PDF manual with the exploded view;

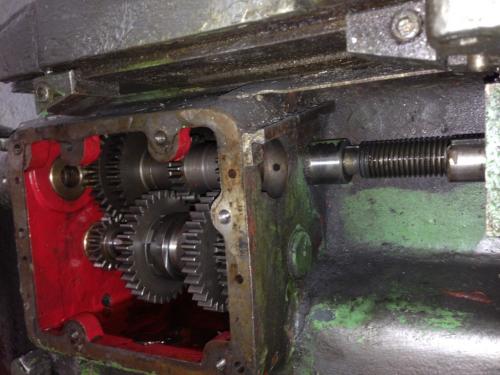

In this photo there should be a shaft with a universal joint at either end, going from the middle left to the top left of the gearbox in the middle of the photo:

This is what I found when I opened up the gearbox:

The circlip is there too if you look closely.

The shaft is supposed to enter the gearbox through the bush at the top left of the above photo, which has a 3/4" bore, then it drives the gear, which has a 7/8" bore, and is supposed to be in this position:

then the shaft exits the gearbox through a bush that is supposed to be in this hole (this hole in the casting is 1.5" diameter);

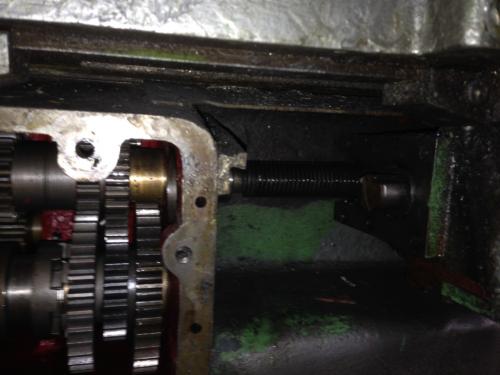

and goes across to this other gearbox, which appears to be where the trouble began:

The second gearbox contains the worm arrangement that sends the drive up to the gear train in the top part of the knee that drives the X axis leadscrew. This gearbox is mounted under the table thus has to move in & out in the y axis, with the shaft sliding through it. I'm deducing that the oil level in this box was neglected (it's sort of hidden under the table) resulting in the worm gear inside it seizing on the shaft, which would have prevented any movement of the table in the Y-axis, so someone has simply cut the shaft either side of where it is seized and removed the remainder. The casing of the worm gearbox is also cracked, presumably from someone trying to force movement in the Y axis after the shaft seized, so i will have to either weld it or make a new one (who do I know who has an iron casting furnace...)

I think I'll have to scan a page of the manual to get the exploded view, will do that later

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

06-11-2015, 02:50 AM

(This post was last modified: 06-11-2015, 02:51 AM by Pete O.)

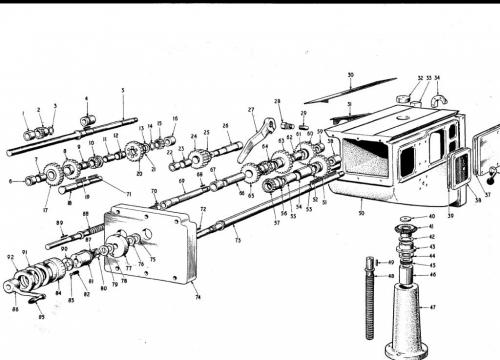

Had to get my daughter to help me with the scanning thing, here's the exploded view; the shaft is item 5. The parts are in misleading positions in this diagram; the bush labeled #4 is the one that is in place at the top left of the gearbox in the above photos; it actually runs on the shaft right where the #5 arrow is pointing. The gear #2 is keyed to the shaft right under where the #4 arrow is pointing, and bush #1 runs immediately right of the flange.

There are 7 different diameters on the shaft, including the flange. A weldment sounds like an excellent idea for the flange, or perhaps a bush pinned in position.

Forgot to mention, the cut part of the shaft that is still in place files easily.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 716

Threads: 32

Joined: Apr 2012

Location: Washington, USA

My final vote is for scrap iron and welding. The weld and keyway are bound to cause warping though. If you're not so handy with that, then you might want another look at 1-1/2" 1045 in the hot roll form and turn it to size. Speedy wants $20 + shipping for 18" of it, not so bad after all.

Of greater concern is the worm. You really don't want to make one of those, so can the old one be rescued?

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

(06-11-2015, 02:14 AM)Pete O Wrote: The casing of the worm gearbox is also cracked, presumably from someone trying to force movement in the Y axis after the shaft seized, so i will have to either weld it or make a new one (who do I know who has an iron casting furnace...)

If your not able to do it yourself (Casting Iron is a whole new level of learning) I would try to get ahold of a guy on yourtube by the handle of

https://youtu.be/WERgTZvfnbw

He's in Oz not sure where, but if it was me I would try to contact him thru one of his videos and see if he would do it. I could but the shipping would be a killer I'm sure.

If the cracks aren't too bad it would be welded, or brazed. do you have a photo of the cracked area?

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

Have a look at this two-part video by Adam Booth - he repairs a cast iron lathe part.

https://www.youtube.com/watch?v=puiNc5EwogI

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

(06-11-2015, 08:13 AM)Sunset Machine Wrote: Of greater concern is the worm. You really don't want to make one of those, so can the old one be rescued?

Yeah if the worm gear can't be rescued the whole job will be a non-starter I think, would make more sense to put an electric drive on the x-axis feed. I'm hoping to get a chance this afternoon to pull the worm gearbox out and investigate.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

|