Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Nothing is ever easy - 70mm square tubing is available but only on special order, so in that case it isn't !@#$#@!@ available is it you !@#$#@!.

Just have to buy 200 tons or some such amount

I'll have to try some more places - may get lucky

Maybe I'll have better luck with the casters - did I heck

. The original caster plate size (on the engine crane) are 95mm x 60mm the smallest plate size I can find with a similar size and load rated wheel is 105 x 85mm, which of course doesn't fit the 72mm square tubing very nicely and the holes don't align

. So I need to look at this a little more closely.

DaveH

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Perhaps this is why people just cut the legs to length. I know that you don't want to do this but if you did, you could make up some short lengths of box section out of flat plate that you could use to join the cut legs back together again.

This will also save you having to dick about finding other casters.

Hunting American dentists since 2015.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(07-31-2015, 08:05 PM)Mayhem Wrote: Perhaps this is why people just cut the legs to length. I know that you don't want to do this but if you did, you could make up some short lengths of box section out of flat plate that you could use to join the cut legs back together again.

This will also save you having to dick about finding other casters.

Think you're right there Darren - I'll have another try Monday for some 70mm square if it is apita then on to the next plan.

I could use 50mm x 75mm rectangular tube, weld a piece 10mm thick on either side of the 50mm and 50+10+10 = 70 could be a way to go.

I think I'm going to end up cutting the legs shorter - a lot less trouble and suits my lazy personality

The casters I'm not too concerned about I'll get something to fit - like a single "bolt hole" type, 100mm diameter, cast iron with a PU tyre and ball bearings - it will run much nicer (oh, and with brakes)

DaveH

Posts: 723

Threads: 34

Joined: Feb 2012

Location: Minneapolis, MN

The following 2 users Like arvidj's post:

EdK (08-02-2015), DaveH (08-13-2015)

(07-28-2015, 07:08 PM)DaveH Wrote: ... of course replace the front legs with shorter ones. Just to give it more mobility in a small space.

DaveH

Just my mind wandering on Sunday morning so you may want to skip this.

Like many others I (a) am getting older and (b) need to lift heavy stuff.

I also own one of the ubiquitous engine cranes that have the long legs. I've often thought about making another set of legs that were considerably shorter but then envision what happens when the center of mass moves past the end of the shorter legs. I think the technical term "it tips over" applies.

I've thought of ways I could resolve the issue ... add mass to the back of the crane as a counterweight ... but that has its challenges.

I though about putting a plate on the back of the crane and then simply stand on it. I certainly qualify with the excess mass thing so problem solved. But then I'd have to step off the plate to actually move the crane ... and the tipping problem reappears.

I also thought about simply putting concrete or some other "heavy thing" on the back of the crane but if permanently affixed the crane becomes cumbersome to move when empty or loaded and if not permanently affixed I'd need another crane to load and unload the counterweight. A Fibonacci crane if you will.

I've come to the conclusion that either an anti-gravity device or an overhead system attached to the basement trusses will be required, but both of these projects are on hold for now.

Arvid

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

You're right Arvid "swings and roundabouts" I'm looking to see how short the legs have to be to lift approx 130 lbs (60 kgs) with the inner part of the jib fully extended. The 130lbs is my 3ton arbor press which is about the heaviest item that gets lifted on and off the bench.

Surprisingly shortening the legs so that the wheels are directly underneath the junction between the outer and inner parts of the jib and the jib horizontal the 130 lbs is lifted without the crane tipping forward. However I can pull down on the jib and it will tip, still have to look at it some more.

Another way I was looking at it was to "wind" the inner extended jib in once the Item has free space underneath it thus reducing the tipping effect.

I think at the end of the day it will be a compromise.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

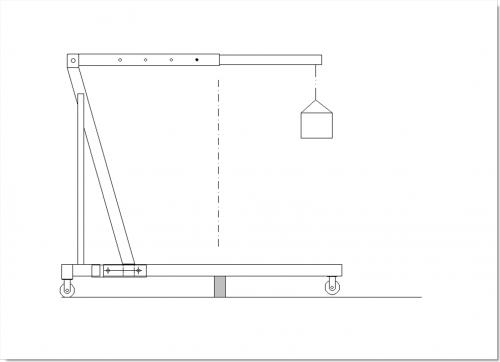

A sketch shows it more clearly. I used a piece of wood to lift the wheels (on the long legs ) off the ground - Move the wood, lift the load (130lbs), see if it tips.

The position shown above the crane didn't tip.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

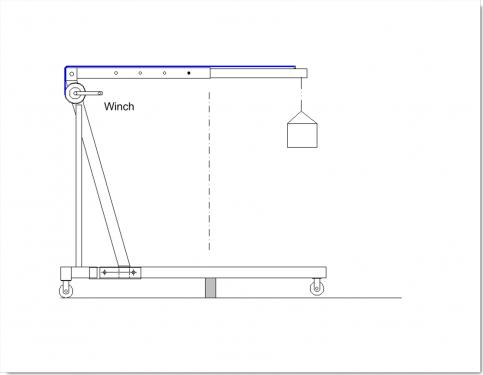

With a winch ? Just a thought.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Seems 70mm sq. tubing is made to order. The next best is 63.5 x 63.5 x4.5mm might seem a strange size but it is 2.5"x2.5" x3/16".

Tomorrow I'll brave the Winter weather and go and pick a length up.

Weld some 5mm thick plates on should do the trick

DaveH

I'll have to try some more places - may get lucky

I'll have to try some more places - may get lucky