12-06-2015, 01:00 AM

It looks like I'm not such a pioneer after all.

Today I found a reference to an archived post on another forum from about 8 years ago, where someone else has already done this conversion on the same furnace. The only difference I can see here is that he made a new front face plate from some sheet aluminum, and was using the face plate itself as a heat sink for the SSR.

I don't know that I would want to do that - dumping the heat into the control panel where you are operating the furnace from.

I want to stick with using a heat sink AWAY from the front panel. But that's just me. It may be perfectly fine to do that, I don't know...

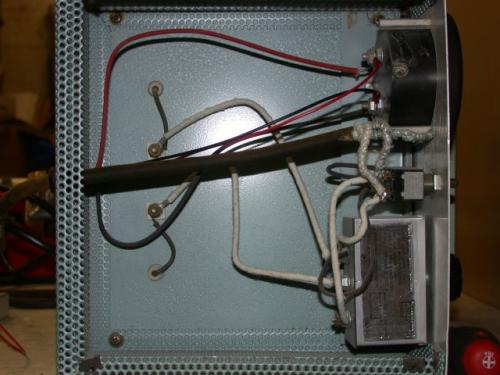

It looks like there will be plenty of space in the enclosure though after the original controls are removed.

I measured mine and think the 18" long thermocouple will be the perfect length. I hope so anyway because I just ordered it along with some misc hardware for putting this all together.

Today I found a reference to an archived post on another forum from about 8 years ago, where someone else has already done this conversion on the same furnace. The only difference I can see here is that he made a new front face plate from some sheet aluminum, and was using the face plate itself as a heat sink for the SSR.

I don't know that I would want to do that - dumping the heat into the control panel where you are operating the furnace from.

I want to stick with using a heat sink AWAY from the front panel. But that's just me. It may be perfectly fine to do that, I don't know...

It looks like there will be plenty of space in the enclosure though after the original controls are removed.

I measured mine and think the 18" long thermocouple will be the perfect length. I hope so anyway because I just ordered it along with some misc hardware for putting this all together.

Willie

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)