01-04-2017, 11:46 PM

Even though I haven't been to work since I broke my shoulder in July, the boss sent me a good bonus with his Christmas card. When I was trying to decide what to use it for, I remembered that I would like to add a power drive to my mill/drill's X-axis. I ordered one off eBay and it arrived in only about a week. Since the eBay listing doesn't say which machines it will fit, I ended up with the wrong one. Good thing I have a machine shop.

If I adapted the drive to fit on the leadscrew, I would have lost 6 or 7 inches of travel. Here's the original arrangement.

I made up an extension mount to give back the travel I would have lost.

And a shaft extension. Trial fitting the Woodruff key after cutting the slot.

Almost done.

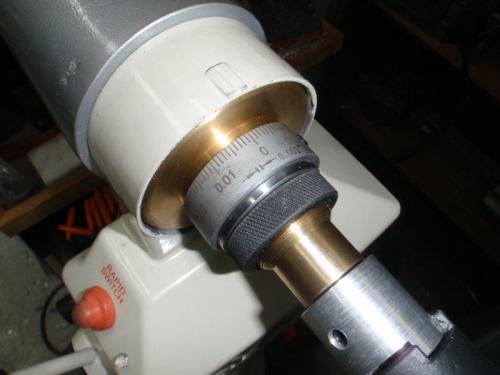

Then, an adapter sleeve to mount the original dial.

I haven't used it much yet. I'm really looking forward to not having to turn the crank on long cuts.

If I adapted the drive to fit on the leadscrew, I would have lost 6 or 7 inches of travel. Here's the original arrangement.

I made up an extension mount to give back the travel I would have lost.

And a shaft extension. Trial fitting the Woodruff key after cutting the slot.

Almost done.

Then, an adapter sleeve to mount the original dial.

I haven't used it much yet. I'm really looking forward to not having to turn the crank on long cuts.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.