Posts: 8,749

Threads: 314

Joined: Feb 2012

Location: Arizona/Minnesota

(03-07-2015, 04:01 PM)PixMan Wrote: ...

I don't need more turning inserts, but these are just the cat's meow for turning aluminum and actually breaking the chip. Because aluminum cuts so easily you can rough at pretty high rates even with a relatively weak geometry. For $5 each (including shipping) they were a fair bargain.

I should look at getting some of those and the tool to use them in. Getting aluminum chips to break would be well worth it.

Ed

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

What are those wheels worth Ken?

Hunting American dentists since 2015.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

(03-07-2015, 07:13 PM)Mayhem Wrote: What are those wheels worth Ken?

They are

worth a small fortune to me for all the work they save me and the nice finishes they leave.

It

cost me $55.

Ed, no need for you to do that. I can help you find inserts which fit the holders you have and achieve the same results.

Just let me know which holders and inserts you currently use.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

I almost forgot to gloat a little. I also received 20 of these ODMT0605ZZN-D57 grade WSP45 inserts for my two Walter 45º face mills. One an older F2280.UB.064.Z04.06 is a Ø 2-1/2 cutter, the other is the newer nickel plated version Ø 3" F4080.UB26.076.Z06.06.

I got the inserts from my employer, they've moved to a newer version of the grade with improved coating, WSP45

S and these are considered "obsolete." Not by me they're not! It's the most "universal" grade as it can handle steel, stainless steel, and superalloys. I'll use them for stainless as I have inserts in the grade WKP35S for steels and cast iron, and WXN15 for aluminum, other non-ferrous and plastic.

![[Image: IMG_20150307_183530628_HDR_zpsminscslp.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20150307_183530628_HDR_zpsminscslp.jpg)

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Hunting American dentists since 2015.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

(03-07-2015, 10:01 PM)Mayhem Wrote:

Thank you.

I can say with some degree of confidence that what I have is likely a lifetime supply.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

EdK (03-08-2015)

(03-07-2015, 10:05 PM)PixMan Wrote: ...I can say with some degree of confidence that what I have is likely a lifetime supply.

The time it is taking me to get my mill up and running I am feeling the same way about my insert inventory

Hunting American dentists since 2015.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 1 user Likes f350ca's post:

PixMan (03-08-2015)

Got this UPS delivery some time ago, as in years, (UPS = Uther Peoples Suff). Don't even remember who gave it to me, thought it was a sedative drill press think they did too. Someone on another forum was parting one out, turns out and it makes sense now, its a Hamilton tapping machine.

![[Image: IMG_1629.jpg]](https://lh4.googleusercontent.com/-tMiH-MWdp_I/VPzyMEH_ncI/AAAAAAAACt4/fiPwHrCyQx8/s1024/IMG_1629.jpg)

The table moves up with the ratcheted handle, force the spindle up and the tap is driven in, pull down on the part and it retracts the tap.

Decided it was worth a clean up, not sure how often it will get used, may have to get into model building.

Dug into the shed and second grab found this vintage GE motor (the first grab rotated the wrong way). Wired up a cord and it spun up almost silently.

![[Image: IMG_1630.jpg]](https://lh6.googleusercontent.com/--LlE7D3LNQY/VPzyMek8-YI/AAAAAAAACt8/OFOE1bAGZ2s/s1024/IMG_1630.jpg)

Free advice is worth exactly what you payed for it.

Greg

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

Ingenious design, give that poor thing some love!

The cone drive/reversal is so cool, it just needs that rust cleared up and some and lots of lube to make it butter smooth again. So much easier to get successfully tapping holes than trying to set torque on a Tapmatic head!

Posts: 2,597

Threads: 99

Joined: Dec 2014

Location: Michigan

The following 1 user Likes Vinny's post:

PixMan (03-09-2015)

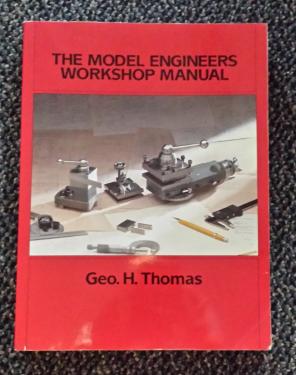

Not UPS but USPS (same letters are there, right?). Arrived today, haven't had a chance to look it over yet but it is in really good condition.

Hmmm, wasn't sideways here: It wasn't sideways here:

http://metalshop.nobucks.net/pix/book.jpg

![[Image: IMG_20150307_183530628_HDR_zpsminscslp.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20150307_183530628_HDR_zpsminscslp.jpg)

![[Image: IMG_1629.jpg]](https://lh4.googleusercontent.com/-tMiH-MWdp_I/VPzyMEH_ncI/AAAAAAAACt4/fiPwHrCyQx8/s1024/IMG_1629.jpg)

![[Image: IMG_1630.jpg]](https://lh6.googleusercontent.com/--LlE7D3LNQY/VPzyMek8-YI/AAAAAAAACt8/OFOE1bAGZ2s/s1024/IMG_1630.jpg)