Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

Odd that your collet block is not the 5C style so common everywhere. Those can handle up to about 30mm. (I have a 1-1/16" and 1-1/8" collet for mine, no metric.)

Now I wonder how you're going to mill the flats if you don't have at least one good drawbar to start with. Do you have one or will you be using some other milling machine?

Your setup looks fine, it'll work.

Posts: 2,597

Threads: 99

Joined: Dec 2014

Location: Michigan

I cheated and bought a hunk of 1" hex stock.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(05-05-2015, 09:45 AM)Mayhem Wrote: I have realized than I have 3mm diameter in which to experiment with DOC etc and see what finish I can get. If I'm not happy on my lathe, I can then move to the faster one. Unfortunately neither have auto feed.

Does that make sense?

Darren, It doesn't make sense to me (but who cares).

How can you worry about FINISH if you only have hand feed?

Why do you care about finish? Isn't functionality the goal.

Or, most probably, I've missed something.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

stevec (05-06-2015)

Ken - my mill came with an ER32 collet chuck and half a dozen ER32 collets (worth almost 1/2 of what I paid for the mill). I picked up a full set of collets when in Hong Kong a couple of years ago (well made and much cheaper than buying them here).

At one point I had been toying with the idea of buying a set of 5C collets and the square and hex blocks that you refer to, for the convenience of quick indexing. However, once I saw that these blocks were available for ER32 collets, it was a no brainier. It simply made more sense to me to stick with the system that I already had in place. You can now buy a spindexer with an adapter to use ER32 collets.

I have a crappy M12 drawbar currently and will either use this and a HSS or solid carbide end mill to cut the flats. I could always make up an equally crappy 1/2-13 drawbar and do the flats with my 4042R shoulder mill. No, a hand file is not an option

Steve - I always care about the finish I get when making something. With patience and concentration, I can get acceptable finishes on the lathe with hand feeding. Whilst I can spend time with a file and emery cloth, the better the finish I get when turning, the less time I spend overall on the project.

Whilst it is a functional item I will see and feel it every time I use it. Each to their own I guess...

Hunting American dentists since 2015.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Interesting that the most recent eBay email I received from my "Kondia" search was for a 4140 drawbar...

Hunting American dentists since 2015.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 4 users Like Mayhem's post:

f350ca (05-09-2015), EdK (05-09-2015), Highpower (05-09-2015), PixMan (05-09-2015)

(05-01-2015, 07:13 PM)stevec Wrote: C'mon Ken, "dirty" you outa know that ain't Darren's style

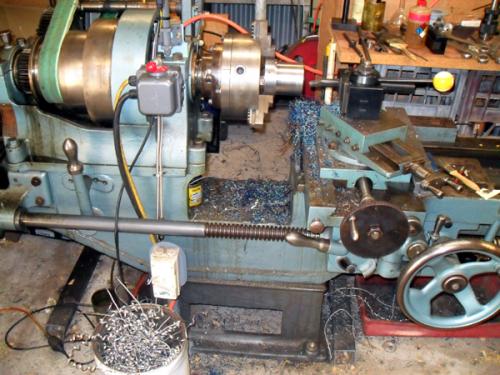

How is this for dirty Steve?

I got tired of using old car radiator hose and wooden wedges to secure long lengths of stock on my lathe, so I turned up a spider for the back of the spindle. The body is about 96mm ø with a 68mm through bore. The bucket in the foreground is predominately from large diameter drilling before boring.

I'm very happy with the finish, despite not having a power feed on this lathe. Tomorrow I'll poke the necessary holes in it.

My next project was the drawbars for my Kondia mill and I only managed to get one machined. I had a lot of trouble turning the 4140 due to long stringy chips. I tried three different inserts and a range of (manual) feeds and DOC's. I was getting very nice finishes at 1600 rpm but couldn't break the chips. Instead, I ended up with a birds nest before I had made a full length cut, more often than not. I tried a Tungaloy CCMT09T304-24 T725X, a Walter CCGT 09T304-PF5 WPP20 and an Iscar CCMT09T304-SM IC907. I found the Iscar insert performed better with a 1.0mm DOC and a really fast feed. However, it certainly wasn't a clear winner and I would have probably gotten the same results with either of the others. I often had to manually break the chips.

My design incorporates a 26 x 13 thrust bearing, with one (well two-thirds) being used for each drawbar. Being a 26 x 13 bearing, one of the races and the bearing assembly itself have the smaller 12mm ID. So, the 12.7mm ground 4140 round was turned down to 12mm and the bearing race and bearing assembly pressed on. Once these were on, the hex drive was fitted (the hex will be milled tomorrow). The 13mm ID bearing race is affixed to a carrier (highlighted below) that is fitted into the top of the spindle, thus completing the thrust bearing assembly regardless of which drawbar is in use.

Next it was flipped over and turned down for the minor diameter for a M12x1.75 thread. Once this was done, the end was single point threaded.

The finished assembly:

Hunting American dentists since 2015.

Posts: 3,002

Threads: 51

Joined: Apr 2012

Location: Ontario

Nice thread Darren

Free advice is worth exactly what you payed for it.

Greg

Posts: 3,795

Threads: 183

Joined: Jun 2012

Location: Farmington Hills, Michigan

I agree. Nice thread Darren.

Did you back the tool out under power or turning the spindle by hand?

Tom

Darren ,,,,,,,,,,,nicely done

Rob

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

Great work Darren!

So all you have to do now is to mill the hex and you have a good drawbar for the holders with M12x1.75 thread, cool! How many of your holders use that thread, how many use a 1/2-13UNC, and some other as well?

I don't know is using a thrust bearing there is good or not. I've seen rotating washers there, but never an actual bearing. Would it allow you to over-torque the threads in the holders? Would it come loose to easily, especially upon reversal when power tapping, or was that shown on the Kondia assembly drawings? Heck, my machine probably has a thrust bearing there and I don't even know it. ;)

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)

Darren ,,,,,,,,,,,nicely done

Darren ,,,,,,,,,,,nicely done